The optimal warehouse designed for your operation

There’s no one-size-fits-all warehouse. Determining the best warehouse location, warehouse layout, and warehouse design requires digging deep into what your operation needs to do. ISD’s engineering and design teams are set up to do just that. We start by understanding your objectives to design the optimal warehouse for you — a warehouse tailored to your industry, accommodated for your constraints, aligned with your budget, and scaled according to your needs.

Supercharging every square foot

Some of our customers start a partnership with us when they’re building a new warehouse. Others bring us on to develop and evolve custom warehouse solutions for existing spaces so they can adapt to changing customer demands. We approach it this way: whether it’s a newly constructed warehouse or an existing one you’ve been managing, our enthusiasm lies in bringing a fresh perspective and expertise to collaborate with you in finding effective solutions.

Efficiency now — and later

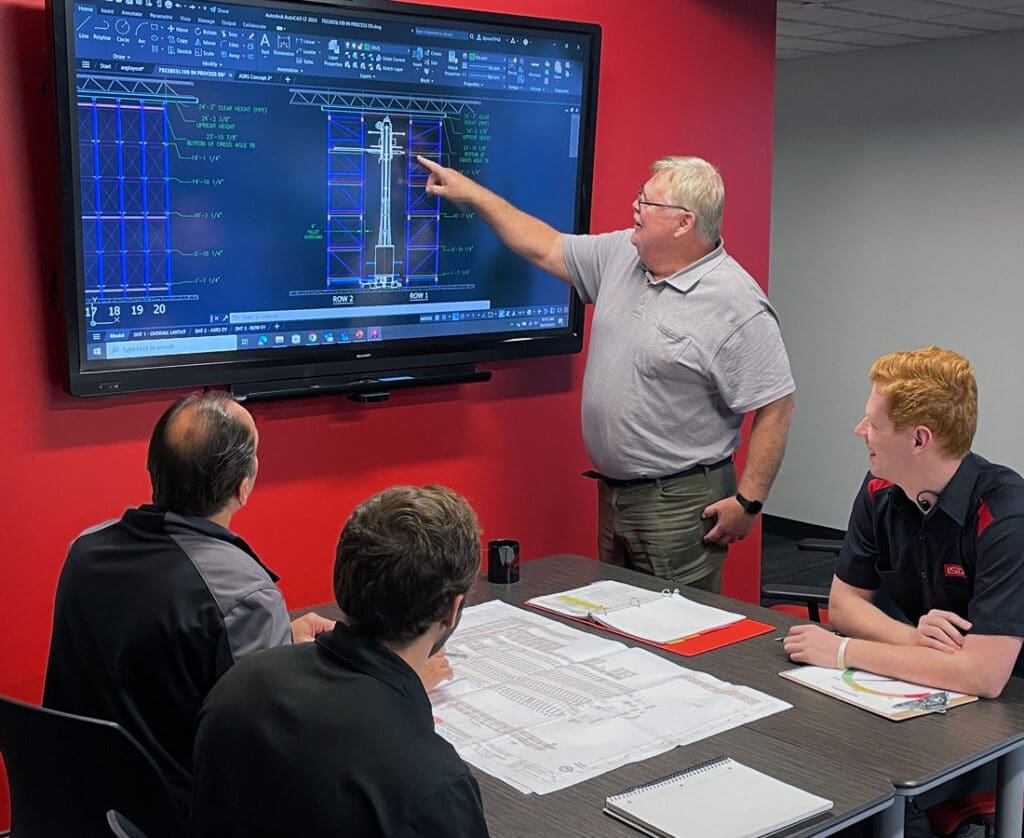

Warehouse system design works best when it’s specific. Before we determine an optimal warehouse design, our engineers get to know your workflows and operations. We work with you to uncover opportunities to improve efficiencies through hardware, software, and process design. Then, we present you with options and collaboratively choose the plan that will bring you the most benefit now and in the future.

We’ve got the details covered

Warehouse managers have to sweat the small stuff. Orders come in from various avenues, such as online platforms, sales team members, and manufacturing partners, but it’s in the warehouse where all orders are fulfilled. The fulfillment process, covering everything from order processing to shipment, involves a multitude of critical details that cannot be overlooked. Partnering with ISD on a warehouse design project means we’ll be working with you side by side, from ideation to final implementation, to get everything right.

Studying first

ISD starts every warehouse design project with system concepting and an engineering study. Our listen-first consulting approach allows us to deeply understand your operation, map out and evaluate possible designs, and work together to determine what’s best for you.

Integrating your WCS

Warehouse control systems (WCS) control the automation equipment in your factory. When partnering with ISD on a warehouse design project, we ensure seamless integration of all your hardware and software components — including the crucial alignment of your WCS with your warehouse management system (WMS).

Bringing it all together

Having the right equipment is crucial, but without a cohesive design, you won’t achieve the efficiency gains you need. Partner with warehouse experts like ISD to maximize the potential of every component, whether it’s basic conveyors or fully automated systems.

Finding maximum utility

It’s not about flashy features. In every warehouse, there are processes suitable for automation and others best handled traditionally. Our engineers design warehouses optimized for maximum productivity, tailored to the specific needs of your operation and the team running it.

Not Sure Where to Get Started with Automation?

Take the first step and visit our automation insights and resources.

Go to Automation Insights

PetMeds achieves 6,000 cartons per hour

Learn how they did it

Magna produces 384 seat pallets per hour

Learn how they did it

Related Services

How We Partner

Consulting

System Integration

Industrial Controls

Where to Get Started with Automation

Customer Support

Request Support

Talk to an Automation Expert

Warehouse design that works.

Our consultants and engineers love solving problems. When it comes to warehouse designs that can make or break a business, we dig in with curiosity, creativity, teamwork, and grit until we’ve found the perfect solution for you. Ready for a free, no-stakes conversation about what ISD can do for you?

Let’s Talk