No programmers needed

Reliable, easy-to-use control systems

A modern materials handling operation is full of high-tech equipment. But you shouldn’t have to be a programmer in order to make the most of it. If your technology could tell you exactly where issues are happening, you could take corrective action without having to shut down your line, damage product, or jam up production while experts come in for the fix. Is it time for a new industrial control system to allow you and your team to be the experts of your operation?

Lighting up problems

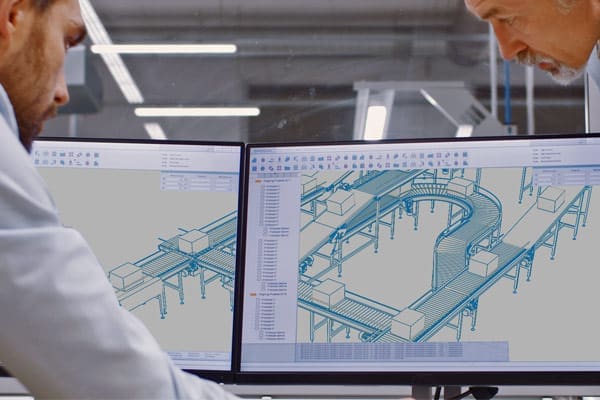

Industrial controls can be simple or complex. On the simpler side, you may need a programmable logic controller (PLC) that allows you to flexibly and reliably control manufacturing processes. PLCs automatically monitor conditions like temperature, pressure, and positioning. They indicate problems via alarms or lights. A more complex system will include a human-machine interface (HMI) that integrates with PLCs to display issues on screens. Partnering with ISD means having a team of curious learners bring decades of systems expertise to design the right controls system for your operation. From simple sensors to detailed displays, you’ll always know what’s happening.

Empowering solutions

Chances are the people working on your production line don’t have extensive programming experience. With an ISD industrial controls system, they don’t need to be programming experts. Our easy-to-use, easy-to-troubleshoot systems provide the user with feedback so your team members know what corrective action they need to take, and where, to keep your production on time. If you have a more complicated problem that requires our help, our controls systems will tell us what the issue is so we know what parts to bring and what type of expert to send so you’re up and running as quickly as possible.

Fewer SOS phone calls

Our goal for industrial controls is to reduce the help calls our customers need to make. Not because we don’t love taking customer calls — we do — but because we want our systems to work so well that our customers don’t need us. Making panicked night calls because something’s wrong on the line means time, money, and focus taken away from your progressing operation. ISD’s automated systems and tools, including human machine interfaces (HMI) displays and other industrial controls, empower you to step back from the day-to-day and meet the future.

Reliable equipment

Industrial controls keep an eye on your system and report on how it’s running. If their component parts are cheaply made or low quality, the system will fail. ISD works with quality suppliers providing top-notch equipment for a controls system you can count on.

ROI for all operations

Big manufacturing and distribution operations may require a controls system. But smaller operations can also benefit from control systems that keep downtime to a minimum, reduce error rate, and empower team members.

No shortcuts

Some providers take shortcuts when they install industrial controls. They may want to save themselves work or to ensure the customer needs to call them for service. ISD doesn’t believe in shortcuts. We’re here to be an enduring part of your team, and that means empowering you to solve issues as efficiently as possible.

Not Sure Where to Get Started with Automation?

Take the first step and visit our automation insights and resources.

Go to Automation Insights

PetMeds achieves 6,000 cartons per hour

Learn how they did it

Magna produces 384 seat pallets per hour

Learn how they did it

Related Services

How We Partner

Consulting

System Design

System Integration

Where to Get Started with Automation

Customer Support

Request Support

Talk to an Automation Expert

Let’s get your controls system up and running.

Transparency you can transact on. Reliable and right-sized. ISD works with operations of all sizes to design, install, and implement industrial control systems that empower your team to keep production running smoothly. Maximize uptime metrics with easy-to-use controls made for real users, by real experts.

Let’s Talk