Meeting the future

The demands placed on material handling operations are continually increasing. Resilience and organization used to be enough to maintain the smooth operation of warehouses and manufacturing facilities. However, with escalating customer demands, evolving competition, and compounded issues related to labor and space constraints, incorporating advanced automation becomes a strategic necessity to sustain growth and operational excellence. A WCS can instantly track and share real-time data across advanced automated operations.

WCS vs. WMS

Your operation may have already taken the first steps in automating your warehouse by investing in a WMS. If you are wondering why a WCS may also be necessary for further automation, you are not alone. Although there can be some crossover in the functionality of a WMS and WCS, the two software play distinctly different roles.

Your WMS works as a planning tool at a high level for all items and orders. A WCS works second-by-second to ensure that all systems in your warehouse are communicating and working in harmony. Information is sent back and forth from the WCS to any of your other management software to ensure an efficient and accurate operation.

Software that simplifies

A busy warehouse has different people and equipment at each stage of its operation. But products can only ship as quickly as the slowest step. WCS controls multiple systems such as automated storage and retrieval systems (AS/RS), conveyors, and order picking and fulfillment systems. By centralizing the control and monitoring of these systems, bottlenecks and problems can be found instantly, ensuring your operation is running at its maximum potential.

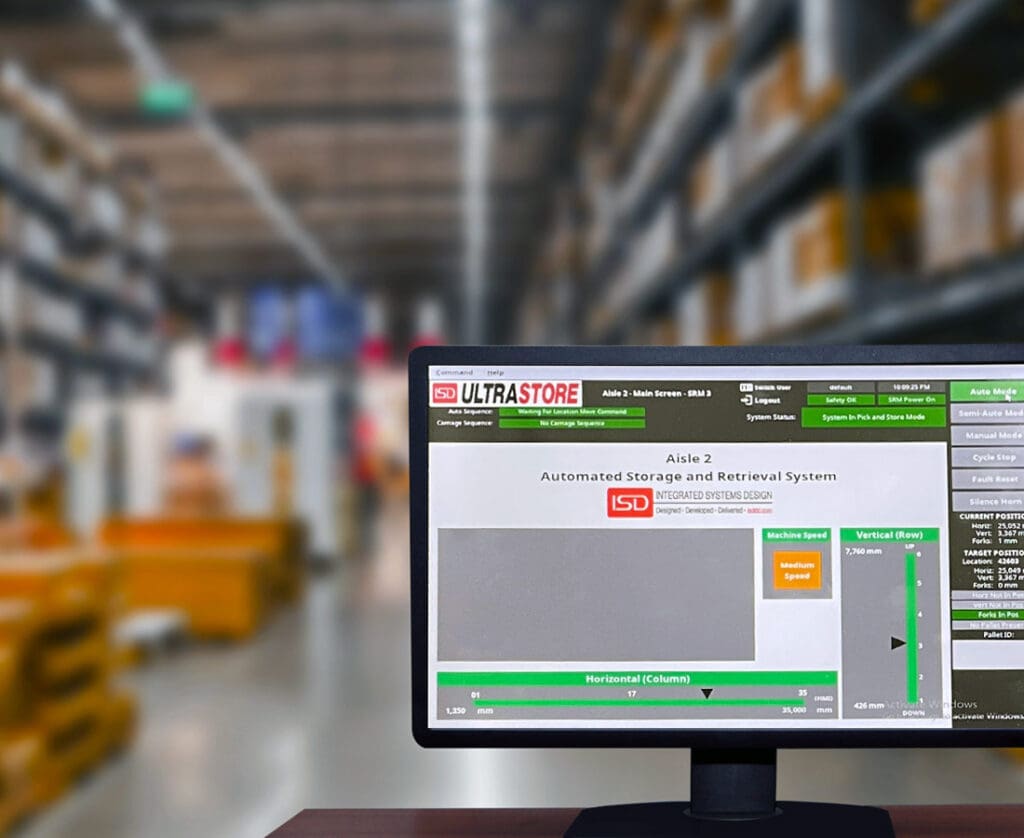

UltraStore WCS

When you invest in an UltraStore AS/RS from ISD, our accompanying UltraStore WCS is seamlessly included, ensuring the optimal utilization of the AS/RS within your operational framework. The UltraStore WCS not only controls the storage locations and item details but also can be customized to your business necessities. In manufacturing, the UltraStore WCS can be linked to sequencing requirements to ensure that products are being loaded onto trailers in the correct order for assembly. In distribution and fulfillment, the UltraStore WCS can optimize your order-picking and replenishment processes, cutting down on labor while maximizing resources. Find out if the ISD UltraStore package is the right fit for you.

Control automation with confidence

Each of our manufacturing, warehouse, and distribution clients comes with unique requirements. However, they all share a common need for software to optimize their investments in automation. Whatever their situation, we recommend and integrate software solutions that drive warehouse operations to peak productivity.

Some software we work with other than WCS include:

Warehouse management system (WMS)

Warehouse management system (WMS): The WMS serves as the central planning and management system for distribution and warehouse operations, integrating with the ERP system for seamless information exchange, including purchase orders, customer orders, client data, and inventory models. It oversees receiving, order allocations, planning, releases, inventory control, replenishments, and migration within the warehouse, offering comprehensive reporting tools for facility-wide performance monitoring. In contrast to MES, WCS, and TMS, which focus on real-time transactions, the WMS excels in master planning for orders and inventory across the facility and external supply chain operations.

Transportation management system (TMS)

Transportation management system (TMS): This software, whether standalone or integrated with WMS/WCS/WES, efficiently handles the entire shipping process. It covers carrier management, cost analysis, rate shopping, dimensional weight management, fleet control, manifesting, and label and paperwork generation. In automated environments, linking it directly to a WMS enables seamless automation of various shipping processes for different modes, including small carton, LTL, truckload, ocean, and air freight.

Warehouse execution system (WES)

Warehouse execution system (WES): A WES, broader than a WCS, addresses areas where WMS may lack real-time control or reporting. It enhances responsiveness and dynamism by handling functions like order planning, dynamic replenishments, and live labor management in real time, allowing the WMS to focus on core planning tasks. The WES streamlines transactional processes, offering more flexibility and control.

Manufacturing execution system (MES)

Manufacturing execution system (MES): This software keeps track of how raw materials are turned into finished products, controls machines on the plant floor, monitors quality control, manages inventory levels, and assists in customer service by facilitating on-time deliveries. ISD works with partners to integrate and install MES solutions.

Controls systems

Controls systems: Industrial controls manage and regulate machinery and processes to ensure the coordination and efficient operation of various material-handling equipment. These controls often involve technologies like programmable logic controllers (PLCs) and human-machine interfaces (HMIs). ISD can design and install the right industrial controls to fit your needs.

Not Sure Where to Get Started with Automation?

Take the first step and visit our automation insights and resources.

Go to Automation Insights

PetMeds achieves 6,000 cartons per hour

Learn how they did it

Magna produces 384 seat pallets per hour!

Learn how they did it

Related Resources

Related Solutions

Automated Storage & Retrieval

Order Picking & Fulfillment

Packing Systems

Shipping Systems

Robotics

Automated Labeling

Cubing & Weighing

Talk with an Automation Expert

Pay for what you need. WCS solutions at the right price.

Whether ISD’s proprietary software is right for you or you’re looking for an enterprise WCS solution, our operations experts are here to set you up for success. We’re on your team.

Let’s Talk