Where to Get Started with Automation

How We Partner

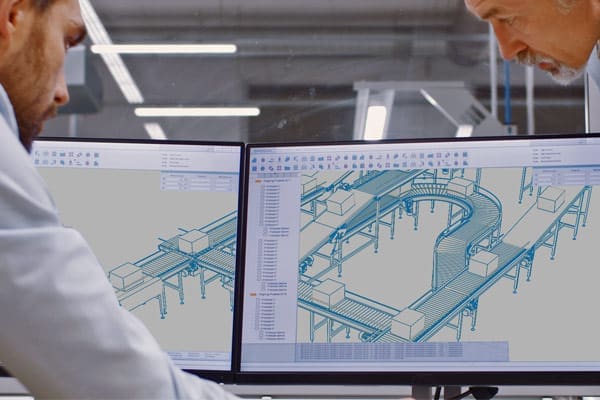

Consulting

System Design

System Integration

Industrial Controls

Customer Support

Request Support

Automation experts

Talk with an automation expert about your operation

Whether you’re looking for a consultant for one specific project, like improving inventory management and storage space utilization, or an engineer to design a new warehouse layout, or an automation expert who can partner with you to optimize warehouse operations from top to bottom, ISD has the experts you need.

Our warehouse optimization engineers have worked on every part of the supply chain, from Tier 1 and Tier 2 suppliers with best-in-class quality control to 3PLs managing unpredictable e-commerce order volume growth.

Automation within reach

The warehouse of the future is waiting

At ISD, we offer a range of warehouse automation services, as well as technology solutions to bring them to life. But no matter the project — from early-stage system design to optimizing warehouse operations and transparency with industrial controls — we see the same challenge come up over and over again:

Increasing expectations. Everyone, at every stage of the supply chain, expects more. Customers want fulfillment centers to pick, pack, and ship their orders faster.

Manufacturers want suppliers to produce just-in-time orders with even tighter quality control and warehouse managers across the board want their teams to be able to meet these increasing expectations despite labor shortages and rising costs.

To rise to these challenges — and the challenges to come — you need to shift your warehouse operations to be easier to manage, run more smoothly, and become a driver for business growth. Warehouse optimization with ISD can do that. Our warehouse automation services cover every operation at any scale.

Meet increasing expectations

Customers expect more

Everyone, at every stage of the supply chain, expects more. We’ll help you deliver.

Tighten quality control

Errors can erase profits

Meet increasing expectations despite challenging labor shortages and rising operational costs.

Rise to the challenges

The right partner is crucial

Rethink your warehouse operations and rise to the challenge of today’s materials handling environment.

We don’t fit your warehouse into our system.

We build a system to fit your warehouse. No matter your current warehouse layout, SKU count, product characteristics or industry, we’ll provide warehouse automation services custom-built for you.

We’re completely brand-agnostic.

Since we represent many industry leading suppliers, we’ll incorporate the right mix of hardware or software to meet your specific needs. We’re brand-agnostic, so you can trust our recommendations to be the best on the market for your budget and warehouse optimization goals.

We’re committed to providing fast ROI.

Evolving your business is stressful. We know you need an investment in automation to pay off. That’s why we commit to providing fast ROI with our warehouse automation services. ISD will map out what improvement to expect, on what time frame, so you only do what makes sense.

From answering questions to providing proposals, we’re ready

Our warehouse automation services can help turn your operations into a driver of business growth now and in the ever-more-complex future. If you’re looking for a team of creative, adaptable experts who are here for the long haul, you’ve found us.

Let’s talk