Scaled for maximum growth potential

Minimizing Labor & Maximizing Efficiency

High-Capacity Order Processing System for Diverse Inventory

- Expand inventory model to include general inventory, nutraceuticals and a controlled section for authentic pharmaceuticals

- Increase order processing volume

- Minimize labor requirements

- Handle over 3,000 orders per hour during peak periods

- Optimize capacity for growth

Challenge: Balancing Labor Costs, FDA Compliance, and High Volumes

PetMeds Faces Packing Challenges Amid Rapid Growth

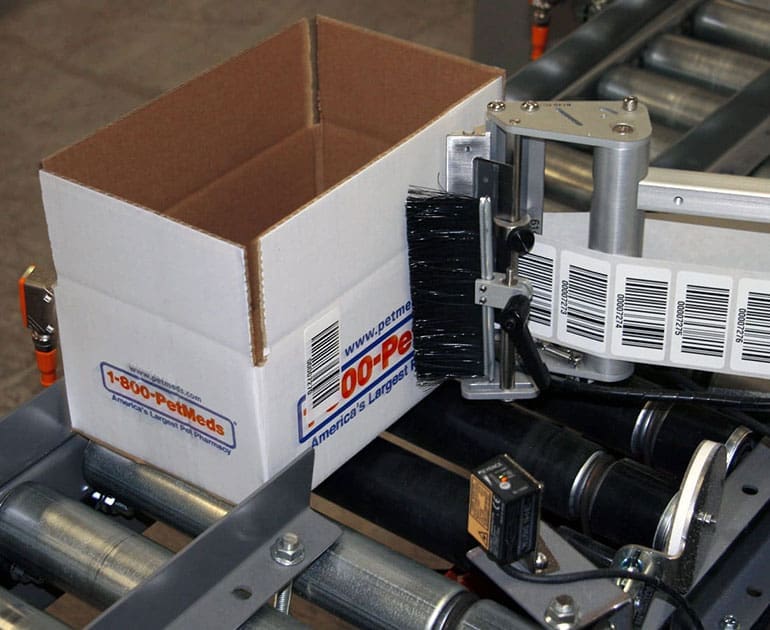

As PetMeds underwent rapid expansion, experiencing double-digit growth year over year, they faced a significant challenge in their packing operations, particularly in the RX area. The packers responsible for handling pharmaceuticals were pharmacists and pharmacy technicians, commanding hourly rates much higher than traditional pickers/packers. With heavy pick volumes, PedMeds needed to pack and ship volumes ranging between 3000 and 4000 cartons per hour. PetMeds aimed to streamline their operations while minimizing labor costs.

Complicating matters further, the pharmacy section had to be securely locked, necessitating separate systems within the building. Compliance with FDA regulations for sealing pharmaceuticals added another layer of complexity. Balancing these demands was crucial, as using pharmacists for picking tasks would be financially unsustainable. Although space was a consideration, it was not the primary concern. Lastly, PetMeds primarily relied on the postal service for delivery, requiring additional certifications for trucks transporting pharmaceuticals.

Pack & ship 3,000+ cartons/ hour

ISD was challenged to develop a seamless system to process over 3,000 orders per hour during peak periods while keeping labor requirements to a minimum.

Reduce labor with increased volume

With increased volume for both pharmacy and nutraceutical products,the system must boost order processing, expand inventory and optimize growth.

Meet FDA Compliance

The pharmacy section had to be securely locked, necessitating separate systems within the building to comply with FDA regulations for sealing pharmaceuticals.

Advanced inventory analysis and customized automation systems achieve order processing rates of 6,000 cartons per hour

Productivity Exceeds 700 Lines/Person/Hour

Efficient System Handles 3,000 Orders/Hour with Minimal Labor

Through seamless integration, our engineered systems efficiently manage over 3,000 orders per hour, necessitating a picking/packing team of 16-18 individuals. With the capacity to handle 6,000 cartons per hour, our system ensures smooth movement of inventory. In the general inventory zone, pickers showcase exceptional productivity, processing over 700 lines per person per hour.

Efficient, regulated pharmaceutical handling

Special provisions for inspections achieves high throughput processing

Special measures were implemented for pharmaceutical items, requiring inspections by pharmacists, allowing associates to efficiently handle several hundred validations per hour. In the dedicated pharmaceutical section, operations reached over 400 lines per hour, with each product requiring specific RX prescription or end-user labeling. All pickers participated in loading final shipping containers, and the system rigorously verified carton weights for accuracy. The downstream manifest process included automated weighing, validation, label application, and sorting based on carrier and service levels, all completed seamlessly without human intervention.

The Results

ISD’s solution resulted in expanding the inventory model to include general inventory, nutraceuticals and a controlled section for authentic pharmaceuticals, increasing order processing volume, and minimizing labor requirement so the operation could handle over 3,000 orders per hour during peak periods.

6,000+ carters per hour

The system’s capacity allowed movement of 6000 carters per hour

3,000+ orders per hour

Systems engineered over 3000 orders per hour

700+ lines per hour

General inventory pickers processed over 700 lines per hour

400+ lines per hour

Pharmaceutical pickers processed over 400 lines per hour