At ISD, we offer a range of warehouse automation services, as well as technology solutions to bring them to life. But no matter the project — from early-stage system design to optimizing warehouse operations and transparency with industrial controls — we see the same challenge come up over and over again.

Whether you’re looking for a consultant for one specific project, like improving inventory management and storage space utilization, or an engineer to design a new warehouse layout, or an automation expert who can partner with you to optimize warehouse operations from top to bottom, ISD has the experts you need.

Our warehouse optimization engineers have worked on every part of the supply chain, from Tier 1 and Tier 2 suppliers with best-in-class quality control to 3PLs managing unpredictable e-commerce order volume growth.

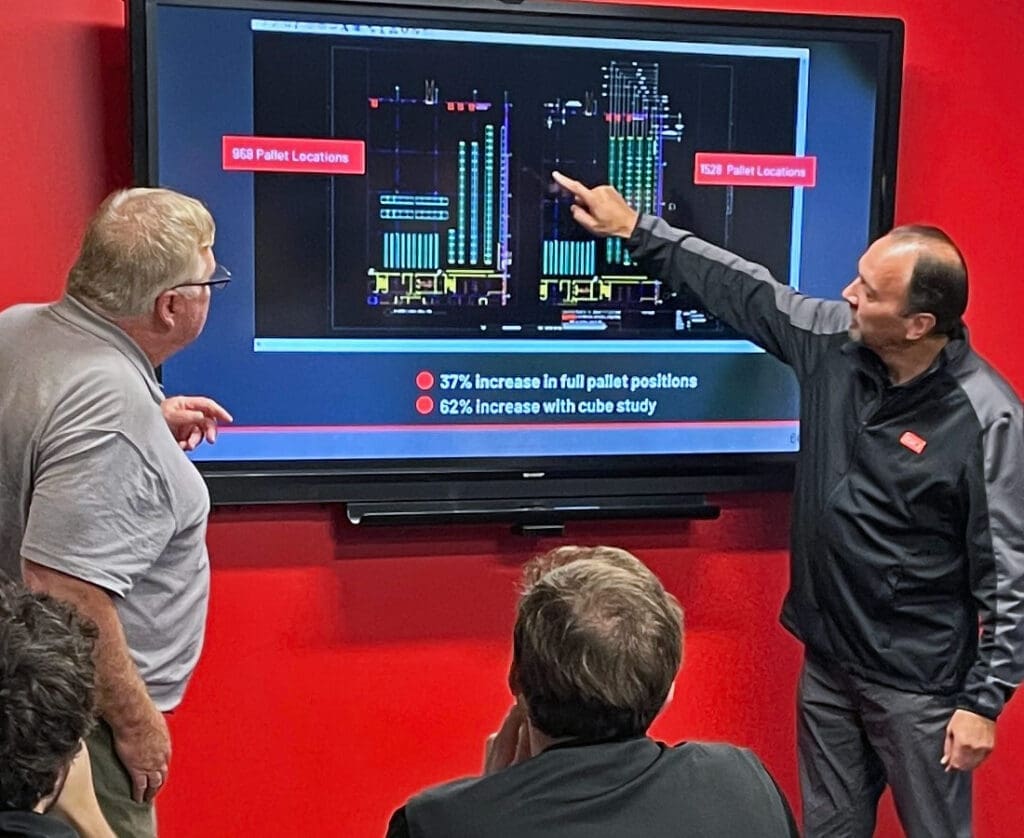

Warehouse system design works best when it’s specific. Before we determine an optimal warehouse design, our engineers get to know your workflows and operations. We work with you to uncover opportunities to improve efficiencies through hardware, software, and process design. Then, we present you with options and collaboratively choose the plan that will bring you the most benefit now and in the future.

Increasing expectations. Everyone, at every stage of the supply chain, expects more. Faster, more accurate, just-in-time, at lower costs, while labor shortages and turnover are real issues. To rise to these challenges — and the challenges to come — you need to shift your warehouse operations to be easier to manage, run more smoothly, and become a driver for business growth. Warehouse optimization with ISD can do that. Our warehouse automation services cover every operation at any scale.

Ready to find your solution? As a systems integrator, ISD continuously looks for leading technologies in both material handling and information systems paired with proven operational strategies. Our solutions range from simple to highly automated, earning us the

trust and business of clients spanning decades.