ISD is at Modex, the material handling industry’s premier event which returns to Atlanta in April 2026. ISD – Integrated Systems Design will showcase decades of warehouse automation expertise at booth B8032. You’ll find practical solutions to your toughest operational challenges.

Modex 2026 takes place April 13-16 at the Georgia World Congress Center. The show brings together supply chain professionals, operations managers, and decision-makers from across North America. This is where you discover what’s working in real warehouses today.

Modex Expo: Where Innovation Meets Implementation

The Modex Expo delivers more than product displays. You get face-to-face access to the people who design, implement, and service automation systems every day.

ISD’s team brings over 60 years of combined experience to booth B8032. We’ve solved problems in retail, ecommerce, automotive, aerospace, and manufacturing facilities. Our engineers have seen what works and what doesn’t.

“The value of Modex isn’t just seeing new technology,” says Ed Romaine, VP Marketing & Business Development at ISD. “It’s having conversations with people who’ve actually installed these systems. You learn what the real ROI looks like, what the implementation challenges are, and how to avoid expensive mistakes.”

New Products introduced Modex Booth Number B8032

- The UltraStore Mini ASRS system provides automated high-density tote and cases-based storage. The system has no single point of failure, doesn’t require an embedded track (like other crane and aisle systems), utilizes off the shelf parts and is Made in the USA.

- URBX Cube Storage piece picking or case handling and sequencing system. This system is capable of reaching 100’ tall and can handle up to 75 lbs. per tote or case. Robots move down the chutes and select the required inventory and then deliver it below to awaiting AMR or conveyor to deliver to a pick station. Another automated system Made in the USA.

Press Conference Unveils Game-Changing Automation

ISD hosts a press conference on Monday, April 13 at 10:30 AM in booth B8032. We’re unveiling two innovative automation systems that address critical market needs.

The presentations showcase solutions tackling the industry’s toughest challenges: maximizing vertical space in constrained facilities and eliminating single points of failure in automated storage.

Both systems represent Made in the USA manufacturing and ISD’s commitment to vendor-agnostic solutions that solve real operational problems. Media, analysts, and industry professionals are invited to attend. You’ll get first access to technical specifications, application details, and implementation timelines for these new offerings.

Three Educational Sessions You Can’t Miss

ISD presents three educational sessions at Modex 2026. Each tackles real-world implementation challenges you’re facing right now.

Goods-to-Person Success Formula: ROI, Risks, and Realities

Monday, April 13, 2:15-3:00 PM in Theater B

Goods-to-person systems promise labor savings up to 65%. But what’s the real payback period? This session cuts through the marketing claims.

You’ll learn how to calculate actual ROI based on your operation. We cover implementation risks that vendors don’t advertise. You’ll understand when goods-to-person makes sense and when it doesn’t.

The session includes real case studies with documented results. No theoretical projections. Just data from operating facilities.

The Latest and Greatest Advances @ MODEX 2026

Monday, April 13, 12:00-12:45 PM in the MHI Industry Group Theater

Presented in association with MHI’s Solutions Community, this session showcases breakthrough technologies making an impact today.

ISD joins other industry leaders to demonstrate innovations that are production-ready. You’ll see what’s moving beyond pilot programs into full-scale deployment.

This isn’t vaporware. These are systems running in facilities right now, delivering measurable improvements in throughput, accuracy, and labor efficiency.

What’s New in ASRS: Breakthroughs Driving the Future of Warehousing

Monday, April 13, 10:30-11:15 AM in Theater C

ASRS technology continues evolving rapidly. This session, presented with MHI’s ASRS Product Section Group, covers the latest developments.

You’ll discover new mini-ASRS solutions that fit smaller operations. Dense storage innovations that maximize vertical space. Integration approaches that connect ASRS with existing warehouse systems.

The presentation includes throughput comparisons, footprint requirements, and cost considerations. You get the technical details you need for informed decisions.

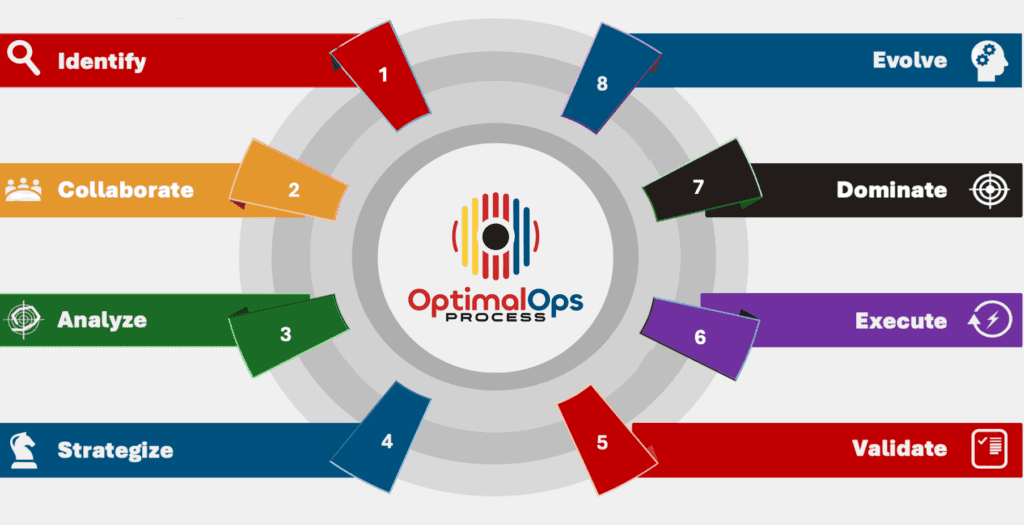

OptimalOps-Process: Our Competitive Advantage

ISD’s OptimalOps-Process differentiates us from competitors. This proprietary methodology ensures optimal solutions, not just equipment sales.

We start with comprehensive data analysis of your operation. SKU velocity, order profiles, seasonal variations, and growth projections all factor into the design. You get systems engineered for your specific requirements.

The process includes vendor-agnostic equipment selection. We partner with leading OEMs across the industry. This means you get the best technology for your application, not whatever one manufacturer offers.

“Being OEM agnostic is crucial,” explains Ed Romaine. “Different operations need different solutions. A 3PL handling ecommerce orders has completely different requirements than an automotive parts supplier. One-size-fits-all doesn’t work in warehouse automation.”

Implementation planning considers your operational constraints. We design around your facility limitations, budget realities, and timeline requirements. The goal is a system you can actually install and operate successfully.

Student Days Partnership

ISD proudly participates in Modex Student Days as a site sponsor. We’ve supported this program for years.

The next generation of supply chain professionals needs exposure to real automation challenges. Student Days provides that connection between classroom theory and warehouse reality.

Our team welcomes student visitors at booth B8032. We discuss career paths in warehouse automation, system integration, and operations management. These conversations help students understand where their skills can make an impact.

Innovation Award Competition: UltraStore Mini ASRS

ISD entered the Modex 2026 Innovation Awards with our newly released UltraStore Mini ASRS system.

The UltraStore Mini brings automated storage to operations previously limited to manual systems. It delivers ASRS benefits in a compact footprint that fits existing facilities.

Key advantages include reduced floor space requirements up to 75%, labor savings of 50-60%, and improved inventory accuracy exceeding 99.9%. The system integrates with existing warehouse management systems.

“The Mini ASRS addresses a market gap,” says Bob Jones, Director of Engineering at ISD. “Many operations need automation but can’t justify a full-scale ASRS. This system provides the automation benefits in a right-sized package.”

Bring Your Operational Challenges

Come to booth B8032 prepared. Bring your facility layouts, throughput requirements, and operational constraints.

Our team can begin the OptimalOps-Process discussion right there. We’ll review your requirements and identify potential solutions. You’ll leave with actionable insights, not just brochures.

We understand you’re evaluating multiple options at Modex. That’s exactly why vendor-agnostic expertise matters. We help you sort through the claims and identify what will actually work in your facility.

Video demonstrations show systems in operation. You’ll see picking operations, storage density comparisons, and throughput capabilities. These aren’t simulations. They’re real systems running in production facilities.

Schedule Your Booth Meeting

Don’t leave your Modex visit to chance. Schedule a booth meeting in advance at booth B8032.

Click here to schedule your booth meeting

Reserved meeting times ensure you get dedicated attention from our team. We’ll prepare for your specific challenges before you arrive. This maximizes the value of your Modex time.

Scheduled consultations typically run 30-45 minutes. Bring your questions, data, and constraints. We’ll provide preliminary analysis and next steps.

Why ISD for Your Automation Project

Choosing a systems integrator matters as much as choosing equipment. Implementation expertise determines project success.

ISD brings 60+ years of warehouse automation experience. We’ve designed solutions for facilities from 50,000 to 1,000,000+ square feet. Our project portfolio spans every major industry vertical.

The OptimalOps-Process ensures you get optimal solutions. Data-driven analysis identifies the right technologies for your operation. Vendor-agnostic selection means we specify what works best, not what’s most profitable to sell.

Our team stays with you through implementation and beyond. Training, maintenance, and ongoing optimization keep your system performing at peak levels. You’re not buying equipment. You’re building a long-term automation partnership.

Start the Conversation Now

You don’t have to wait until Modex to begin planning your automation project.

Click here to schedule a free consultation now

Early conversations help you prepare better questions for the show floor. You’ll know which technologies to evaluate and what specifications matter for your operation.

A free consultation covers your operational challenges, growth projections, and automation objectives. We provide preliminary recommendations and budget ranges. This groundwork makes your Modex visit far more productive.

The consultation requires no commitment. You get expert guidance whether you’re ready to proceed now or planning for next year.

See You in Atlanta

Modex 2026 offers unmatched access to warehouse automation expertise and innovation. ISD’s presence at booth B8032 gives you the opportunity to engage with seasoned professionals who’ve solved challenges like yours.

Attend our educational sessions. Learn what really drives ROI in goods-to-person systems and ASRS implementations. Discover the latest technological advances from industry leaders.

Stop by for fresh popcorn and substantive conversations about your operational challenges. Bring your data. Bring your questions. Leave with actionable solutions.

The warehouse automation landscape continues evolving. Labor constraints tighten. Space becomes more expensive. Customer expectations rise. Standing still isn’t an option.

“Every operation faces unique challenges,” concludes Ed Romaine. “But the fundamentals remain constant. You need more throughput with less labor in tighter spaces. The technology exists to deliver that. The question is finding the right combination of solutions for your specific operation. That’s what we do every day.”

Schedule your booth meeting or free consultation today. Your competition is already planning their automation strategy. Don’t get left behind.