Comprehensive Guide to Industrial Warehouse Racking Systems: Optimizing Storage Density and Operational Efficiency

Today’s warehouse operations demand strategic performance for your industrial warehouse racking systems, pallet racking systems, and storage racking systems. The right industrial racking system transforms available cubic space into productive storage capacity while supporting operational goals.

North America dominated the global pallet racking market with 36% market share in 2024. The U.S. pallet racking market is valued at $3.31 billion in 2025 and is predicted to reach $7.53 billion by 2034, growing at 9.53% annually, according to Precedence Research.

This guide examines the primary warehouse racking systems, their specific applications, and key selection criteria for maximizing storage density and throughput efficiency.

Understanding Industrial Warehouse Racking Systems

Warehouse racking comprises metallic structures designed to support unit loads, including pallets, boxes, and containers. These systems enable vertical space utilization, dramatically increasing storage capacity compared to floor-level stacking methods.

Storage system selection directly impacts operational metrics: inventory accessibility, order fulfillment velocity, labor efficiency, and space utilization. We recognize that no two warehouse operations operate identically, requiring customized storage solutions rather than one-size-fits-all approaches.

The Evolution of Storage Technology

Today’s storage systems represent significant advances from basic adjustable pallet racking to versatile, dynamic solutions adaptable to specific business requirements. Modern warehouse automation integrates racking infrastructure with material handling equipment, warehouse management systems, and robotics to create cohesive operational ecosystems.

Selective Pallet Racking Systems

Selective racking systems serve as the workhorses of warehouse storage, characterized by direct accessibility to every pallet position. These systems remain the most widely implemented storage configuration across industries.

Pallet Racking Key Characteristics for Industrial Warehouse Racking Systems

Selective pallet racking utilizes forklifts to access goods via parallel aisles, providing immediate access to all stored unit loads. Each pallet occupies a dedicated position with standard aisle widths accommodating conventional forklift equipment.

Operational Industrial Warehouse Racking Systems Applications

We implement selective storage racking systems for operations requiring:

- High SKU variety with frequent inventory rotation

- Direct pallet accessibility for order picking

- Mixed product lines with varying turnover rates

- Distribution centers supporting e-commerce fulfillment

- Automotive parts distribution requires diverse inventory

This system proves ideal for businesses with dynamic inventory, including retail, e-commerce, and automotive operations.

Performance Advantages

Selective storage racking systems deliver operational flexibility through:

- 100% pallet selectivity and accessibility

- Straightforward inventory management protocols

- Simple reconfiguration for changing SKU profiles

- Lower capital investment compared to high-density alternatives

- Compatibility with standard material handling equipment

Very Narrow Aisle (VNA) Racking Systems

VNA pallet racking systems represent a compact selective racking variant, creating higher storage density without requiring additional square footage.

System Design for VNA

VNA pallet racking systems and storage racking systems compress storage through narrowed aisles, achieving space savings exceeding 40% with minimum aisle widths of 1.5 meters. This configuration demands specialized handling equipment designed for narrow-aisle operation.

Implementation Considerations

VNA systems optimize facilities with:

- Limited floor space requires maximum density

- Sufficient ceiling height for vertical storage

- Investment capacity for specialized lift trucks

- Controlled traffic patterns minimizing congestion

- Operations prioritizing storage density over picking velocity

Double-Deep Racking Systems

Double-deep pallet racking systems store pallets at two depths, achieving substantially higher storage density than selective configurations.

Operational Design

Unlike standard selective storage racking systems, operators lack direct access to all stored pallets in double-deep configurations. Systems require specialized forklifts equipped with telescopic forks or pantograph mechanisms for accessing second-depth pallets.

Strategic Applications

We recommend double-deep storage racking systems for:

- Operations storing substantial quantities of identical SKUs

- Beverage distribution with high-volume product lines

- Manufacturing facilities managing raw material inventory

- Distribution centers with moderate turnover rates

- Facilities prioritizing storage density over complete selectivity

Double-deep storage racking systems prove most beneficial for businesses maintaining substantial quantities of the same product.

Drive-In and Drive-Through Racking Systems

Drive-in and drive-through systems address high-density storage requirements by minimizing aisle space, allowing forklifts to drive directly into racking structures.

System Variations

Drive-in systems feature single entry and exit points, while drive-through configurations provide access on both sides, delivering enhanced operational flexibility. Drive-in racking creates storage tunnels with angle rails supporting pallets at multiple levels, with lift trucks accessing tunnels for pallet storage and retrieval.

Ideal Operating Environments

These systems suit industries where space constraints dominate and inventory turnover remains relatively low, including cold storage facilities. Drive-in configurations support Last-In-First-Out (LIFO) inventory management, while drive-through systems enable First-In-First-Out (FIFO) rotation.

Drive-in racking can extend up to 10 pallets deep, representing the most cost-effective high-density storage option.

Performance Considerations

Drive-in and drive-through systems deliver:

- Maximum cubic space utilization through vertical and horizontal density

- Reduced infrastructure costs through minimized aisle requirements

- Bulk storage capacity for large quantities of identical SKUs

- Effective cold storage solutions minimizing refrigerated square footage

Given direct forklift interaction with structures, frame uprights remain susceptible to collision damage. We recommend implementing upright protection systems to safeguard structural integrity and maintain safety compliance.

Pushback Racking Systems

Pushback racking enhances warehouse storage efficiency by supporting pallets stored 2-5 deep, accessible from the same aisle.

Operational Mechanics

Pushback systems utilize inclined rails, sliding carts, and double lanes. When employees load pallets onto systems, pallets push subsequent pallets backward; during unloading, pallets automatically advance to the front position.

Strategic Applications

Pushback racking suits operations requiring:

- Bulk storage with moderate SKU variety

- LIFO inventory management protocols

- High storage density with improved selectivity versus drive-in systems

- Retail distribution supporting seasonal inventory fluctuations

- Rapid pallet access without forklift lane penetration

This warehouse storage racking systems strategy proves ideal for storing bulk items for retail distribution.

Pallet Flow Rack Systems

Pallet flow rack systems, commonly called gravity flow racks, optimize space and inventory management through gravity-driven mechanisms enabling automatic stock rotation on a First-In-First-Out basis.

System Design

Pallets slide down inclined rollers or wheels, reducing manual labor requirements. Racking rails feature slight inclinations where palletized goods are inserted at upper points and move toward lower exit points via rollers.

Critical Applications

Pallet flow systems suit industries with strict inventory control requirements, including food and beverage distribution. This method proves especially critical in food and beverage industries for managing perishable goods, optimizing inventory freshness, and significantly reducing waste through expiration prevention.

Operational Benefits

Pallet flow racking delivers:

- Automatic FIFO rotation eliminating manual stock management

- Reduced labor costs through gravity-powered movement

- Improved inventory accuracy and expiration date management

- High-density storage with excellent pallet accessibility

- Enhanced order picking productivity through organized presentation

Flow racks prove common in distribution centers, food and beverage industries, and warehouses where strict inventory rotation remains critical.

Carton Flow Racking Systems

Carton flow racking represents a FIFO high-density storage system ideal for storing cartons and light unit loads, including boxes and small products.

Performance Characteristics

These systems serve as space savers and efficient stock controllers. Carton flow substantially upgrades cost savings by organizing products and rotating stock automatically, dramatically improving warehouse efficiency.

Cost Efficiency

Because systems utilize gravity as a free power source, operations can achieve 25% to 75% labor cost savings. This makes carton flow particularly attractive for order fulfillment operations that process high volumes of small items.

Cantilever Racking Systems

Cantilever racking systems prove famous for being safe, efficient, and easily accessible, suitable for indoor and outdoor applications in single-sided or double-sided configurations.

Design Advantages

Cantilever systems utilize steel posts with protruding arm-like brackets capable of supporting light, medium, or heavy loads. Arms remain vertically adjustable to accommodate changing inventory profiles.

Strategic Applications

Cantilever systems excel at storing:

- Lumber and building materials

- Steel bars and metal extrusions

- Piping and tubing

- Furniture and bulky items

- Carpet rolls and textiles

Cantilever represents the ideal shelving solution for housing long or bulky products.

Key Selection Criteria for Industrial Warehouse Racking Systems

Selecting optimal racking configurations requires comprehensive analysis of multiple operational factors.

Inventory Characteristics

The size, shape, quantity, and weight of inventory requiring storage affect the type of material handling and storage solution warehouses utilize. Pallet dimensions, weight distributions, and product fragility directly influence system selection.

Spatial Constraints

Warehouse facility layout determines ideal pallet racking systems for operations. The amount of floor space in warehouses plays a significant role in choosing racking systems. Vertical space available impacts storage system height capabilities.

Accessibility Requirements

Warehouse employees and operators must access pallets and stored materials quickly and efficiently. Operations require high selectivity and benefit from selective or VNA configurations, while bulk storage operations accept reduced accessibility for density gains.

Material Handling Equipment

When selecting warehouse racking systems, consider existing material handling equipment limitations. Certain equipment types better handle inventories of different heights and weights. Specialized systems, including double-deep and VNA configurations, require specific forklift capabilities.

Industrial Warehouse Racking Systems Investment Considerations

Warehouse and distribution center budgets remain essential in deciding what types of pallet racking systems to implement. High-density racking systems, including flow or drive-in racks, may carry higher upfront costs but maximize storage space and potentially reduce costs associated with additional warehouse space.

While maintaining budgets remains vital for meeting financial goals, low-priced options may not always prove optimal. We evaluate total cost of ownership, including installation, maintenance, and operational efficiency over system lifecycles.

Safety and Compliance

Employee safety represents a priority for warehouse operations. Storage systems that are structurally sound, durable, and designed for specific locations and applications provide optimal safety for operations and staff.

The OptimalOps-Process™ Approach to Storage System Selection

At ISD, we recognize that effective storage racking systems and pallet racking systems represent only one component of comprehensive warehouse optimization. Our OptimalOps-Process™ framework evaluates storage requirements within broader operational contexts.

Comprehensive Operational Analysis

We begin with detailed data analysis examining:

- Current and projected inventory profiles

- Order fulfillment methodologies

- Throughput requirements and velocity metrics

- Space utilization and expansion capabilities

- Material handling equipment compatibility

Integrated Solution Design

Many warehouses utilize multiple racking system (pallet racking systems and storage racking systems) types in operations due to requirements for accommodating products of various weights and sizes. We design integrated solutions combining complementary technologies:

- Selective storage racking systems for fast-moving SKUs

- High-density systems for bulk inventory

- Flow racking for perishable goods management

- Automated storage for maximizing cubic utilization

Future-Proof Planning

We design systems supporting operational evolution. This includes:

- Modular configurations accommodating SKU profile changes

- Scalable infrastructure supporting growth

- Integration capabilities with warehouse automation

- Flexibility for seasonal volume fluctuations

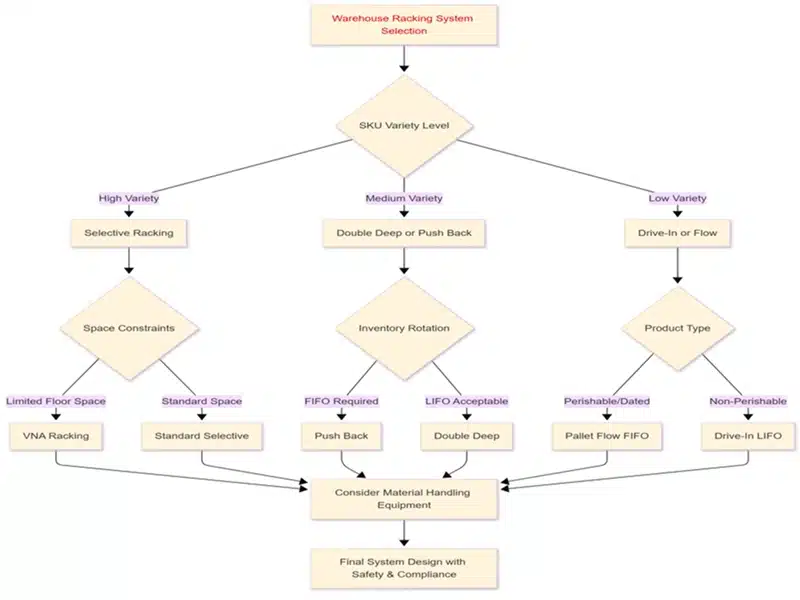

Industrial Warehouse Racking Systems Decision Framework:

Implementing Industrial Warehouse Racking Systems: Best Practices

Professional Design and Engineering

In the most complex storage systems, structural calculation, load and resistance studies, and seismic calculations conducted by specialist technical teams remain essential. We provide comprehensive engineering analysis, ensuring structural integrity and code compliance.

Installation Excellence

Designing effective warehouse racks remains crucial, but installation proves equally important as design. Professional installation ensures:

- Proper anchor bolt specification and placement

- Structural alignment and plumb tolerances

- Load capacity verification

- Safety equipment integration

Ongoing Industrial Warehouse Racking Systems Optimization

Warehouse operations evolve continuously. We support:

- Regular system inspections and maintenance

- Reconfiguration for changing requirements

- Capacity audits and utilization analysis

- Safety compliance monitoring

Conclusion: Strategic Storage for Operational Excellence and Industrial Warehouse Racking Systems

Industrial warehouse racking systems represent fundamental infrastructure investments influencing operational efficiency for years. The optimal system balances storage density, accessibility, throughput velocity, and investment constraints while supporting business growth trajectories.

The type of industrial racks warehouses should choose depends on multiple factors, including goods characteristics, turnover rates, and warehouse dimensions.

At ISD, we combine 60+ years of systems integration experience with our OptimalOps-Process™ framework to deliver storage solutions optimizing every cubic foot of warehouse space. Our comprehensive approach examines pallet racking systems and storage racking systems within broader material handling ecosystems, integrating conveyor systems, ASRS, AMRs, and warehouse management software into cohesive operational platforms.

If you’re building new warehouses, improving current ones, or planning to grow, choosing the right racking system can significantly enhance how much you can store, how efficiently workers can operate, and how smoothly everything runs.

About ISD – Integrated Systems Design

ISD is a leading systems integrator specializing in warehouse, distribution, and manufacturing operations with over 60 years of experience providing distribution and manufacturing strategy planning. As an OEM provider of the UltraStore Mid-Load ASRS system, ISD brings an OEM-agnostic approach to selecting the best automation solutions for each client’s unique operational requirements.

Our proprietary OptimalOps-Process™ features an 8-step framework designed to enhance operational efficiency, reduce costs, expedite ROI, and future-proof operations by optimizing picking, sorting, packing, and shipping processes before automation deployment.

ISD’s extensive offerings encompass Conveyor Systems, Automated Storage and Retrieval Systems (ASRS), Autonomous Mobile Robots (AMRs), Robotics, Sortation Systems, Warehouse Software, Pallet Handling, Packaging Automation, and comprehensive Order Fulfillment technologies.

We focus on working together with clients to set goals, analyze data thoroughly, and create plans that prepare them for successful manufacturing automation readiness.

For expert guidance on warehouse storage racking systems and pallet racking systems selection and implementation, contact ISD at information@isddd.com or visit www.isddd.com, email information@isddd.com or schedule a no-obligation consultation.