Home / Services / OptimalOps-Process

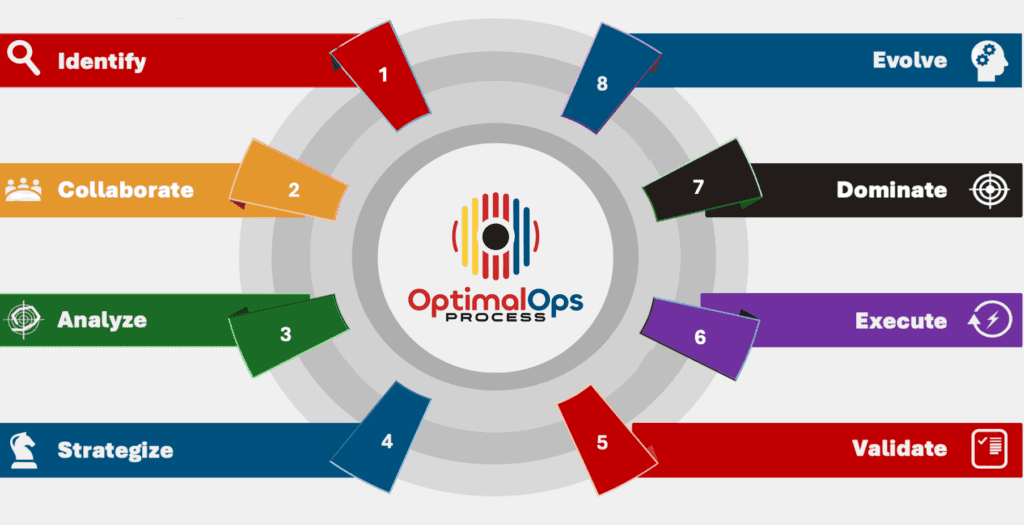

Are you tired of warehouse operations that drain your resources while delivering mediocre results? From a simple work cell or zone to an entire green or brown field rework, welcome to ISD’s revolutionary 8-Step OptimalOps-Process – your gateway to warehouse automation excellence. At Integrated Systems Design (ISD), we don’t just implement solutions; we transform your entire operational landscape through our meticulously crafted OptimalOps Process. This isn’t another cookie-cutter approach – it’s a comprehensive methodology that has helped organizations achieve unprecedented success in their automation journey.

When you partner with ISD, you’re not gambling with your business future. Our OptimalOps-Process delivers measurable outcomes that speak for themselves. We’re talking about on-time and on-budget delivery, maximum labor savings, complete floor space optimization, and 100% accuracy – metrics that directly impact your bottom line.

Too many integrators and OEMs talk about success, ISD follows an intricate 8-step process to help assure maximum results. With our OptimalOps-Process, we’ve eliminated the guesswork and created a systematic and analytical approach that consistently delivers exceptional outcomes.

Here’s what sets us apart from the competition – we’re not married to any single technology or vendor. Our technology-agnostic lens means we evaluate the best solutions based on what’s required for YOUR business, not what’s most profitable for us. This unbiased approach ensures you get the perfect blend of automation, software, processes, procedures, and training tailored specifically to your unique requirements.

Every successful automation project begins with a crystal-clear understanding. In the Identify phase, we dive deep into your current operations, examining your goals, objectives, operational headaches, and challenges that keep you up at night. At ISD, we don’t just scratch the surface – we conduct comprehensive analysis that reveal the scope and direction your facilities and operations truly require. This isn’t about what we think you need; it’s about understanding what YOU actually need to succeed. ISD doesn’t chase the “shiny new technology penny,” but rather focuses on reaching success regardless of the technology. During this phase, ISD will partner with your team to uncover hidden inefficiencies, identify bottlenecks that are costing you money, and determine the exact pain points that need addressing. It’s like having a diagnostic check-up for your entire operation.

Innovation doesn’t happen in isolation. The Collaborate phase brings together every perspective, skill, and idea from your organization and ours. We believe that the best solutions emerge when diverse minds work together toward a common goal. This collaborative approach ensures that solutions aren’t just technically sound but also practically implementable within your organizational culture. Frontline workers have insights that executives might miss, and the management team has strategic vision that operators might not see. ISD will help bring it all together. Think of this phase as building a dream team where everyone’s voice matters. The result? Solutions that are far more innovative, comprehensive, and likely to succeed because they’ve been crafted with input from every stakeholder who will be affected by the changes.

Numbers don’t lie, and neither do we. The Analyze phase involves performing an in-depth data analysis that validates what your business really requires. We don’t make assumptions or rely on gut feelings – we let the data guide our recommendations. Our analysis goes beyond surface-level metrics. We examine throughput patterns, seasonal variations, error rates, labor costs, space utilization, and dozens of other factors that impact your operations. This comprehensive analysis ensures that our recommendations are based on solid evidence, not wishful thinking. By the end of this phase, you’ll have a clear, data-backed understanding of where you are, where you need to go, and exactly what it will take to get there.

Strategy without tactics is just wishful thinking, but tactics without strategy is just busy work. In the Strategize phase, we review your organization’s business case, growth plans, and opportunities through our technology-agnostic lens. This is where we determine the perfect blend of automation, software, processes, and procedures that will help ensure your success. We’re not just thinking about today – we’re planning for your future growth and evolving market demands. Our strategic approach considers your budget realities, timeline requirements, staff capabilities, and long-term business objectives. The result is a comprehensive roadmap that balances immediate improvements with sustainable long-term growth.

Before we move forward, we take a step back and validate everything. The Validate phase involves taking a holistic view of the proposed solution, clearly defining what success looks like, and ensuring that our optimal solution perfectly matches your organization’s unique personality and business requirements. This isn’t just a technical review – it’s a comprehensive validation that considers company culture, operational preferences, and strategic objectives. We make sure that every aspect of the solution aligns with your vision and capabilities. Think of this as a final quality check, a measure twice and cut once moment before manufacturing and installation begins. We want to be absolutely certain that what we’re about to build will deliver the results you expect and deserve.

Implementation is where dreams become reality, and we don’t leave anything to chance. The Execute phase involves implementing our detailed roadmap while meticulously aligning people, materials, and processes into your successful outcome – on time and on budget. Our execution methodology has been refined through years of successful implementations. We know exactly what can go wrong and how to prevent it. Our project management approach ensures that every milestone is met, every stakeholder is informed, and every detail is handled with precision. During this phase, you’ll see your vision taking shape as our team works tirelessly to transform your operations. We maintain constant communication, provide regular updates, and address any challenges immediately as they arise.

Installation is just the beginning – domination is the goal. The Dominate phase focuses on training, staff adoption, and flawless implementation that exceeds your KPI and ROI requirements. We don’t just want you to succeed; we want you to dominate your market. This phase includes comprehensive training programs that ensure your staff not only knows how to use the new systems but also understands how to maximize their potential. We work with your team to make them comfortable and confident with the new processes. Our goal is to generate an unfair competitive advantage for your operations. When your operations run smoother, faster, and more accurately than your competitors, your customers notice – and they stay loyal.

The business world never stands still, and neither should your operations. The Evolve phase ensures your systems run at peak levels from day one and continue improving into the future. We help you adapt and change to meet your customers’ and the market’s ever-changing demands. This ongoing support includes system optimization, performance monitoring, technology updates, and strategic planning for future enhancements. We’re not just a vendor – we’re your long-term partner in operational excellence. Think of this phase as having a personal trainer for your warehouse operations. We keep pushing you to achieve better results while ensuring you stay ahead of industry trends and technological advances.

How often have you heard promises about on-time, on-budget delivery only to be disappointed? With our OptimalOps Process, this isn’t a promise – it’s our practice. Our systematic approach eliminates the common pitfalls that cause delays and cost overruns. We achieve this through meticulous planning, experienced project management, and proactive problem-solving. Every potential issue is identified and addressed before it can impact on your timeline or budget.

Labor costs continue to rise while skilled workers become harder to find. Our OptimalOps-Process is designed to maximize your labor savings without compromising operational quality. We identify opportunities for automation that deliver the highest return on investment. But we don’t just automate for automation’s sake. We strategically implement solutions, processes and procedures that allow your existing workforce to focus on higher-value activities while material handling automated systems handle repetitive, error-prone tasks.

Real estate is expensive, and wasted space is wasted money. Our process includes comprehensive space optimization that maximizes your facility’s potential. We analyze your current space utilization and design solutions that dramatically increase storage density and operational efficiency.Whether you’re looking to expand capacity within your existing facility or maximize the efficiency of a new space, our optimization strategies deliver measurable improvements in utilization.

Errors are costly – they damage customer relationships, increase labor costs, and hurt your reputation. Our OptimalOps-Process includes built-in accuracy controls that virtually eliminate operational errors. Through careful system design, comprehensive training, and ongoing monitoring, we ensure that your operations achieve and maintain 100% accuracy levels that exceed industry standards.

In today’s competitive marketplace, operational efficiency isn’t just nice to have – it’s essential for survival. Our OptimalOps-Process doesn’t just improve your operations; it transforms them into a competitive weapon. When you can fulfill orders faster, more accurately, and at lower cost than your competitors, you win more business. When your customers experience superior service levels, they become loyal advocates for your brand.

Every investment in automation should deliver measurable returns, and our OptimalOps-Process is designed to maximize your ROI from day one. We don’t just focus on initial cost savings – we optimize for long-term value creation. Our strategic approach considers all aspects of ROI, including labor cost reduction, space optimization, error elimination, throughput improvement, and customer satisfaction enhancement. The result is a solution that pays for itself quickly and continues delivering value for years to come.

If your business is growing rapidly and your current operations are struggling to keep pace, the OptimalOps-Process is perfect for you. We specialize in creating scalable solutions that grow with your business. Our approach ensures that the systems we implement today can handle your projected growth for years to come. You won’t outgrow your automation investment – instead, it will enable and accelerate your growth.

Are you dealing with chronic accuracy problems, labor shortages, space constraints, or customer service issues? These operational headaches are exactly what the OptimalOps-Process is designed to solve. We’ve helped companies overcome every type of operational challenge imaginable. Whatever problem is keeping you up at night, we’ve probably solved it before – and we can solve it for you too.

Ready to transform your operations and achieve the results you’ve been dreaming of? Getting started with ISD’s OptimalOps-Process is easier than you might think. The first step is simply reaching out to our team for an initial consultation. During this conversation, we’ll learn about your current challenges, discuss your goals, and determine how the OptimalOps-Process can help you achieve unprecedented success. Remember, this isn’t just about implementing technology – it’s about transforming your operational approach to create sustainable competitive advantages that drive long-term business success. Don’t let another day pass struggling with inefficient operations when a proven solution is within reach. Contact ISD today and discover how the OptimalOps-Process can revolutionize your business.

The warehouse automation landscape is filled with vendors making big promises but delivering disappointing results. ISD’s 8-Step OptimalOps-Process cuts through the confusion and delivers outcomes that transform your business operations. From the initial Identify phase through the ongoing Evolve support, every step of our process is designed to maximize your success while minimizing risk. With proven results including on-time delivery, maximum labor savings, complete space optimization, and perfect accuracy, the OptimalOps-Process isn’t just another methodology – it’s your blueprint for operational excellence. The question isn’t whether you can afford to invest in the OptimalOps Process. The real question is whether you can afford not to. Every day you delay is another day your competitors will gain an advantage, another day of operational inefficiencies costing you money, and another day of missed opportunities. Your journey to warehouse automation success starts with a single decision. Make it today.

The timeline varies depending on project complexity and scope, but most implementations are completed within 4-18 months. During the consultation period, we’ll provide a detailed timeline specific to your project requirements.

Unlike vendors tied to specific technologies, we evaluate the full gamut of solutions based solely on what’s best for your business. This unbiased approach ensures you achieve optimal results rather than solutions that benefit the vendor most.

Our decades long experience is backed by our proven methodology, our veteran team, and comprehensive quality controls built into every phase of the process. We’ve refined our approach through decades of successful implementations.

The works equally well for retrofitting existing operations and designing new facilities. We customize our approach based on your specific situation and constraints.

Our relationship doesn’t end at implementation. The Evolve phase includes ongoing support, system optimization, performance monitoring, and strategic planning to ensure your continued success and adaptation to changing market demands.

With parts made specifically for your system and technicians trained with the technology, you can count on ISD for seamless care. Trust our automation experts for a level of support that you can be confident in.