UltraStore Mid-Load Automated Storage and Retrieval System (ASRS)

Home / Technology / UltraStore Mid-Load Automated Storage and Retrieval System (ASRS)

The UltraStore Mid-Load Automated Storage and Retrieval System (ASRS) represents a sophisticated warehouse automation solution designed to handle medium-weight inventory items with exceptional precision and efficiency. This advanced system combines robotics, intelligent software, and mechanical engineering to create an automated storage environment that dramatically transforms how organizations manage their inventory operations. Unlike traditional manual storage methods, the UltraStore Mid-Load ASRS operates as a fully integrated solution that can store, locate, and retrieve products without human intervention, making it an invaluable asset for businesses seeking to optimize their warehouse operations.

Organizations implement the UltraStore Mid-Load ASRS to address multiple operational challenges simultaneously. The system serves as the backbone of modern warehouse management, enabling companies to maximize their storage density while minimizing the physical footprint required for inventory storage. When integrated into existing operations, this automated system allows organizations to achieve remarkable improvements in order fulfillment accuracy, inventory tracking precision, and overall operational efficiency. Companies utilize this technology to eliminate the time-consuming manual processes traditionally associated with inventory management, such as walking through aisles, climbing ladders, and manually searching for specific items.

The strategic implementation of UltraStore Mid-Load ASRS enables organizations to respond more effectively to market demands and customer expectations. By automating the storage and retrieval processes, companies can process orders faster, reduce labor costs, and maintain consistent service levels regardless of seasonal fluctuations or market volatility. This system particularly benefits organizations dealing with high-volume operations, complex inventory requirements, or strict accuracy standards where human error can result in significant operational and financial consequences.

Interested in Discussing Horizontal Carousel Storage?

Key Features, Subsystems and Components of UltraStore Mid-Load ASRS

The UltraStore Mid-Load Automated Storage and Retrieval System incorporates several critical subsystems that work harmoniously to deliver optimal performance. The core mechanical components include precision-engineered storage racks, high-speed shuttles, and vertical lifting mechanisms designed to handle medium-load capacities efficiently. The control system features advanced algorithms that optimize storage locations, manage inventory flow, and coordinate multiple simultaneous operations while maintaining system safety and reliability.

Safety subsystems represent another crucial component, incorporating multiple redundancies and fail-safe mechanisms to protect both equipment and personnel. These safety features include emergency stop systems, collision avoidance technology, and comprehensive monitoring capabilities that continuously assess system performance. The integration capabilities allow seamless connection with existing warehouse management systems, enterprise resource planning software, and other automation equipment. Additionally, the modular design philosophy enables organizations to customize the system configuration according to their specific operational requirements and facility constraints.

Interested in Discussing Your Storage Challenge with Us?

How UltraStore Mid-Load ASRS Helps Your Organization

The UltraStore Mid-Load Automated Storage and Retrieval System transforms organizational efficiency by addressing fundamental challenges that plague traditional warehouse operations. This advanced automation solution eliminates the bottlenecks commonly associated with manual inventory management, enabling organizations to achieve consistent, predictable performance levels that directly impact customer satisfaction and business profitability. The system’s ability to operate continuously without breaks, shifts, or performance degradation means organizations can maintain optimal productivity levels around the clock.

From a strategic perspective, implementing UltraStore Mid-Load ASRS positions organizations to scale their operations more effectively. As business demands fluctuate, the system can adapt to handle varying inventory volumes without requiring proportional increases in labor costs or facility space. This scalability proves particularly valuable for growing businesses that need flexible solutions capable of accommodating expansion without major infrastructure overhauls. The system’s data collection capabilities provide organizations with unprecedented visibility into their inventory operations, enabling data-driven decision-making that improves overall business intelligence.

The financial impact of UltraStore Mid-Load ASRS extends beyond immediate operational savings. Organizations experience reduced insurance costs due to improved safety records, lower facility overhead through optimized space utilization, and decreased inventory carrying costs through better stock rotation and accuracy. The system’s ability to minimize product damage during handling and storage translates directly to improved profit margins, while the enhanced inventory accuracy reduces the costs associated with stockouts, overstock situations, and obsolete inventory.

Benefits of UltraStore Mid-Load ASRS

The UltraStore Mid-Load Automated Storage and Retrieval System delivers comprehensive advantages that revolutionize warehouse operations across multiple dimensions. These benefits extend far beyond simple automation, creating a cascading effect of improvements that enhance every aspect of inventory management and organizational efficiency.

- Dramatic Space Optimization: The system maximizes vertical storage capacity while minimizing floor space requirements, enabling organizations to store significantly more inventory within existing facilities or reduce real estate costs through more efficient space utilization.

- Enhanced Operational Accuracy: Automated processes eliminate human error in inventory tracking, picking, and placement, resulting in accuracy rates exceeding 99.9% and dramatically reducing costly mistakes that impact customer satisfaction.

- Significant Labor Cost Reduction: By automating repetitive tasks, organizations can redeploy human resources to higher-value activities while reducing dependency on manual labor for routine warehouse operations.

- Improved Inventory Visibility: Real-time tracking capabilities provide complete transparency into inventory levels, locations, and movement patterns, enabling better demand planning and inventory optimization strategies.

- Accelerated Order Processing: Automated retrieval processes dramatically reduce order fulfillment times, enabling faster customer service and improved competitive positioning in markets where delivery speed matters.

- Enhanced Safety Performance: Elimination of manual handling for elevated storage reduces workplace injuries, creates safer working environments, and decreases liability exposure for organizations.

- Consistent 24/7 Operations: The system operates continuously without fatigue, breaks, or performance degradation, enabling round-the-clock productivity that maximizes facility utilization and customer service capabilities.

- Reduced Product Damage: Precise handling mechanisms minimize product damage during storage and retrieval operations, protecting inventory investments and maintaining product quality standards.

- Energy Efficiency Optimization: Modern systems incorporate energy-efficient components and intelligent power management features that reduce operational costs and support sustainability initiatives.

- Scalable Growth Accommodation: Modular design enables organizations to expand system capacity incrementally as business needs evolve, providing flexible growth solutions without major infrastructure disruptions.

Applications for UltraStore Mid-Load Automated Storage and Retrieval System ASRS

The versatility of UltraStore Mid-Load ASRS makes it suitable for diverse operational applications across various business contexts. Understanding these applications helps organizations identify optimal implementation strategies that align with their specific operational requirements and business objectives.

- Order Fulfillment Centers: Perfect for e-commerce and distribution operations requiring rapid, accurate order processing with high daily volume requirements and strict accuracy standards for customer satisfaction.

- Manufacturing Support Operations: Ideal for storing work-in-process inventory, raw materials, and finished goods in manufacturing environments where just-in-time delivery and inventory accuracy are critical for production efficiency.

- Pharmaceutical Storage Solutions: Excellent for storing medications, medical devices, and healthcare products where temperature control, contamination prevention, and regulatory compliance are essential requirements.

- Automotive Parts Management: Suitable for managing complex automotive component inventories with thousands of SKUs, varying sizes, and critical availability requirements for production line support.

- Electronics Component Storage: Perfect for handling sensitive electronic components requiring controlled environments, static protection, and precise inventory tracking for quality assurance.

- Food and Beverage Operations: Ideal for storing packaged foods, beverages, and related products where first-in-first-out rotation, temperature control, and contamination prevention are crucial operational requirements.

- Retail Distribution Networks: Excellent for retail chains managing seasonal inventory, promotional products, and regular merchandise requiring efficient distribution to multiple store locations.

- Third-Party Logistics Services: Perfect for logistics providers managing multiple client inventories requiring segregation, accurate tracking, and flexible handling capabilities for diverse product types.

- Spare Parts Management: Ideal for organizations maintaining large inventories of replacement parts, maintenance supplies, and service components requiring long-term storage and occasional retrieval.

- Raw Material Warehousing: Suitable for storing manufacturing inputs, production supplies, and industrial materials requiring organized storage and efficient retrieval for production scheduling.

Factors to Consider When Implementing UltraStore Mid-Load Automated Storage and Retrieval System ASRS

Successfully implementing UltraStore Mid-Load Automated Storage and Retrieval System requires careful consideration of multiple factors that influence both initial deployment success and long-term operational effectiveness. Organizations must evaluate their current operational requirements, future growth plans, and facility constraints to ensure optimal system configuration and performance. The planning phase should include comprehensive analysis of existing workflows, integration requirements with current systems, and identification of potential operational disruptions during implementation.

Facility infrastructure represents a critical consideration that affects both system design and implementation costs. Organizations must assess structural requirements, electrical capacity, environmental controls, and space availability to accommodate the system’s physical and operational requirements. The evaluation should include analysis of floor loading capacity, ceiling height restrictions, and accessibility requirements for maintenance and system expansion. Additionally, organizations need to consider the impact on existing operations during installation and develop strategies to minimize business disruption.

Financial planning extends beyond initial capital investment to include ongoing operational costs, maintenance requirements, and expected return on investment timelines. Organizations should evaluate total cost of ownership including energy consumption, maintenance contracts, software licensing, and potential upgrade costs over the system’s expected lifecycle. The analysis should also consider financing options, tax implications, and the financial impact of improved operational efficiency on overall business performance. Integration requirements with existing warehouse management systems, enterprise software, and other automation equipment require careful planning to ensure seamless operational flow and data consistency across all business systems.

Options and Accessories for UltraStore Mid-Load ASRS Systems

The UltraStore Mid-Load Automated Storage and Retrieval System offers extensive customization options and accessories that enable organizations to tailor the solution to their specific operational requirements. These enhancements extend the system’s capabilities and optimize performance for diverse applications and industry requirements.

- Advanced Control Software Packages: Sophisticated warehouse management integration modules that provide enhanced inventory optimization, predictive analytics, and advanced reporting capabilities for comprehensive operational visibility and control.

- Environmental Control Systems: Temperature and humidity monitoring and control accessories that maintain optimal storage conditions for sensitive products requiring specific environmental parameters for quality preservation.

- Safety Enhancement Packages: Additional safety features including advanced collision avoidance systems, enhanced emergency stop mechanisms, and comprehensive safety monitoring that exceed standard safety requirements for high-risk environments.

- Load Handling Specialization: Customized load handling accessories designed for specific product types including telescopic forks, specialized grippers, and adaptive handling mechanisms that accommodate diverse packaging and product configurations.

- Integration Interface Modules: Advanced connectivity options that enable seamless integration with existing enterprise systems, including ERP software, warehouse management systems, and other automation equipment for comprehensive operational coordination.

- Capacity Expansion Components: Modular expansion accessories that enable organizations to increase system capacity incrementally, including additional storage levels, extended runway systems, and supplementary handling equipment.

- Maintenance Support Tools: Specialized maintenance accessories including diagnostic equipment, predictive maintenance sensors, and remote monitoring capabilities that optimize system uptime and reduce maintenance costs.

- Power Management Systems: Energy optimization accessories including regenerative braking systems, intelligent power management, and backup power solutions that enhance energy efficiency and ensure operational continuity.

- Data Analytics Packages: Advanced analytics and reporting accessories that provide detailed performance metrics, operational insights, and optimization recommendations for continuous improvement initiatives.

- Customization Hardware: Specialized mounting systems, custom fixtures, and application-specific accessories that adapt the system for unique operational requirements or challenging installation environments.

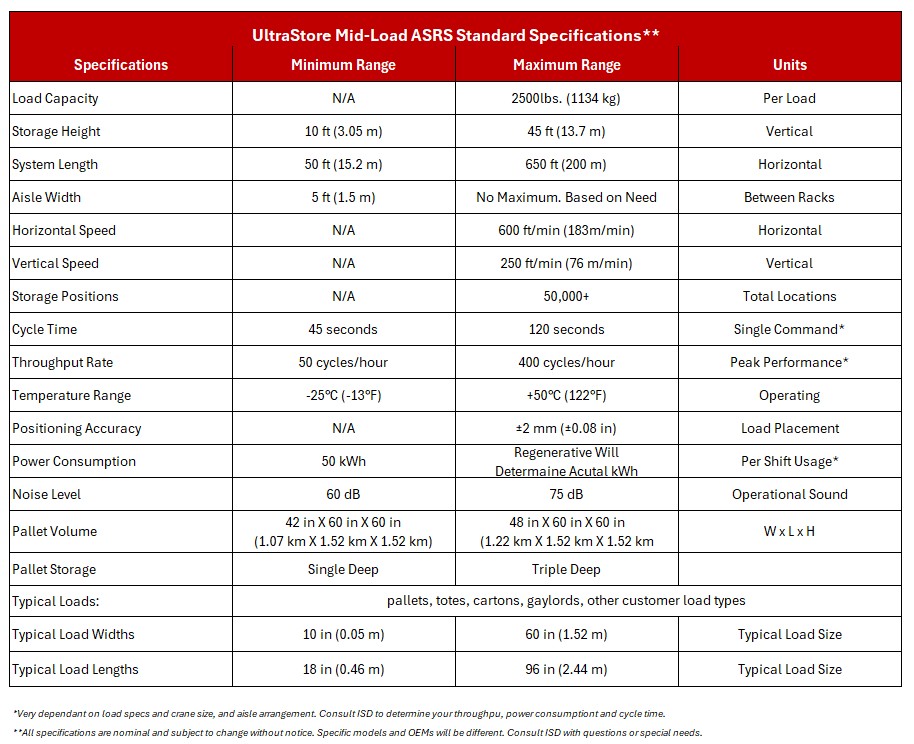

Technical Specifications for UltraStore Mid-Load ASRS

Schedule a No-Obligation Consult Today!

We respect your privacy. We will only use your email address to send you valuable resources. We will not share you information. View our privacy policy. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.