Articles

Discover invaluable insights into the automation industry straight from the experts: gain access to tips, tricks, advice, and in-depth information pertaining to the material handling sector.

Case Studies

With over three decades of experience, ISD has delivered solutions to a wide range of industries. We craft customized solutions for our clients that are tailored to their specific business requirements, while building upon the proven successes of our history.

-

Vitacost Streamlines Operations in New Facility

-

The Repair Clinic doubled system capacity, increased efficiency with automated process

-

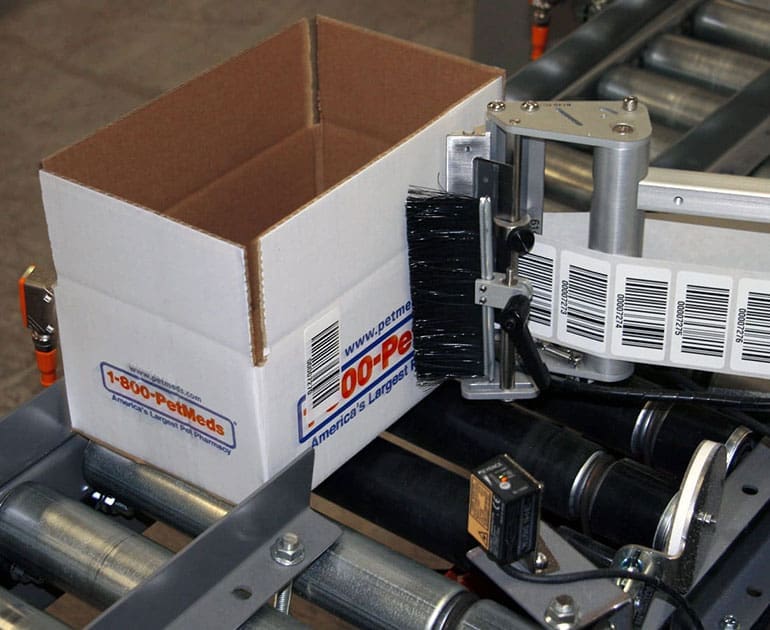

PetMeds® Partners with ISD to Optimize Expansion: Streamlining Operations and Boosting Processing Capacity

-

Streamlined conveyance, automated storage and sequencing of seats ensures that Automotive Assembly Plants don’t miss a beat

Find resources on hardware, software, services, and solutions.

Check out Insights for access to the latest guides, articles and case studies. Find technical documentation or explore product and service content by industry. Can’t find what you need? Call us today.