PetMeds Success Story: A Case Study in Automation Excellence

PetMeds Streamlines High-Volume RX Packing

PetMeds, America’s trusted pet pharmacy, experienced double-digit growth that placed mounting pressure on its order fulfillment operations. As package volumes surged to 3,000+ cartons per hour, including nearly half being true prescription medication fulfillment, the company relied heavily on licensed pharmacists and pharmacy technicians—roles with premium labor costs—to manage picking, packing, and inspection operations.

This model became increasingly unsustainable as order volumes soared. To maintain service quality while controlling costs, PetMeds turned to Integrated Systems Design (ISD) to evaluate their packing workflows and introduce automation tailored to the specialized requirements of pharmaceutical fulfillment.

Balancing Speed, Compliance, and Cost

PetMeds faced a unique set of challenges due to its pharmaceutical & over the counter product mix and regulatory environments. High labor costs and strict packaging requirements demanded a smarter solution to sustain growth without overspending on personnel.

– Process over 3,000 cartons per hour with minimal labor, including orders containing RX product and pharmacist / pharmacist tech level product replenishment, picking, and inspection.

– Maintain FDA compliance with secure, isolated systems

– Reduce dependency on high-cost pharmacy staff for fulfillment

PetMeds Chooses ISD and the Power of the OptimalOps-Process

PetMeds selected ISD for its deep experience in regulated order fulfillment and its proven OptimalOps-Process for warehouse analysis and optimization. ISD conducted a detailed inventory flow analysis across pharmacy and general inventory zones, identifying inefficiencies tied to labor bottlenecks and packaging compliance. The OptimalOps-Process revealed opportunities to segment workflows, automate validations, and scale throughput while maintaining FDA compliance. This structured, data-driven approach. enabled ISD to design a solution tailored specifically to the operational and regulatory demands of a high-volume pharmaceutical distribution center.

ISD Implements a Scalable, Compliant Fulfillment Solution

ISD implemented an advanced, integrated automation system capable of handling over 3,000 orders per hour, over 30,000 per day during, peak volume month while maintaining out the door service timelines with small package carriers.

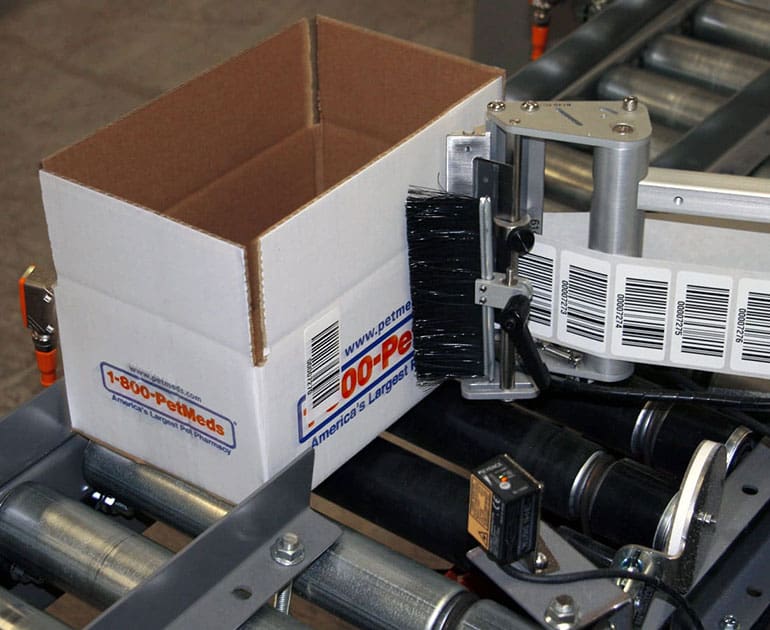

The solution included automated order picking systems, downstream shipping automation, and dedicated pharmaceutical handling with built-in inspection protocols. General inventory workers processed over 800 lines per person per hour, while pharmaceutical staff achieved over 400 lines per hour thanks to automation that supported secure labeling and RX validation. The fully integrated system reduced labor needs, ensured FDA compliance, and scaled effortlessly to meet peak demand.

Download Full Case History

Meet With Us

Cut through the complexity and realize your operation's full potential

Ready to find your solution? As a systems integrator, ISD continuously looks for leading technologies in both material handling and information systems paired with proven operational strategies. Our solutions range from simple to highly automated, earning us the

trust and business of clients spanning decades.