Home / Technology / ASRS / Ultra Batch Dynamic

How the UltraBatch™ Dynamic Batch Pick Workstation Will Increase Your GTP Investment

Your expensive automation systems are underperforming. That ASRS, goods-to-person system (GTP), or pick-to-light (PTL) installation you invested millions in could deliver 33%* more throughput with one strategic addition. The UltraBatch Dynamic Batch Pick Workstation transforms any existing automation into a productivity powerhouse.

This isn’t another picking solution competing with your current systems. The UltraBatch is a force multiplier that makes your existing automation work harder, faster, and more efficiently. You get up to 33% more output from the same equipment investment while achieving 99.9% accuracy levels that eliminate costly errors.

Operations managers at leading distribution centers rely on UltraBatch workstations to maximize ROI from their new or existing automation investments. They report 50%** labor reductions, extended order cutoff times, and throughput increases that handle peak season volumes without proportional cost increases. The math is simple: your current automation handles more orders with fewer operators while maintaining perfect accuracy.

* per operator/station improvement. ** system labor reduction using UltraBatch. *** total system throughput based on average number of workstations/labor, before and after.

What is an UltraBatch Dynamic Batch Pick Workstation and How to Use an UltraBatch Dynamic Batch Pick Workstation

An UltraBatch Dynamic Batch Pick Workstation is an intelligent order batching system that optimizes picking operations for any goods-to-person, ASRS, or pick-to-light automation technology. The workstation dynamically groups orders based on commonality and logical sequence, then automates the batch management process to eliminate operator inefficiencies.

The system integrates seamlessly with your existing automation infrastructure. Whether you operate horizontal carousels, vertical lift modules, AutoStore systems, or traditional ASRS, the UltraBatch workstation becomes the productivity multiplier that unlocks your automation’s full potential.

Step-by-Step Operation Process:

Dynamic Order Queuing – The UltraBatch software analyzes incoming orders and groups them by SKU commonality, order size, and shipping requirements. This intelligent batching eliminates the inefficient single-order picking that wastes automation capacity.

Dynamic Order Queuing – The UltraBatch software analyzes incoming orders and groups them by SKU commonality, order size, and shipping requirements. This intelligent batching eliminates the inefficient single-order picking that wastes automation capacity.Benefits of an UltraBatch Dynamic Batch Pick Workstation

UltraBatch workstations deliver measurable improvements that justify investment through reduced labor costs, increased accuracy, and enhanced automation ROI. These benefits compound across your entire operation to create sustainable competitive advantages.

UltraBatch workstations enhance productivity across diverse picking environments where automation systems require optimization. The technology adapts to various operational requirements while maintaining consistent performance improvements.

The UltraBatch workstation combines intelligent software with ergonomic hardware design to create an integrated solution that enhances any automation system. Each component works together to eliminate inefficiencies while maximizing operator productivity.

The dynamic batching software provides the intelligence that sets UltraBatch apart from static picking systems. The software analyzes order characteristics in real-time, grouping orders by SKU commonality, container size, and shipping requirements. This intelligent grouping minimizes the number of automation presentations required while maximizing picks per presentation.

Ergonomic workstation design positions order containers at optimal heights for operator comfort and efficiency. Up to 15 order totes at an ergonomic work level allow simultaneous order processing while the center position handles single-line orders automatically. This configuration eliminates unnecessary movements while maintaining visual access to all active orders.

Pick-to-light displays provide clear visual guidance for item placement and quantities. The lights integrate with order container positions to show exactly where items belong and how many pieces to place. This visual confirmation eliminates errors while maintaining a consistent picking pace regardless of operator experience.

Automated conveyor systems handle all order induction and discharge activities without operator intervention. The workstation automatically brings new orders to position and removes completed orders to the next operation. This automation eliminates manual handling tasks that create bottlenecks and reduce throughput.

Real-time monitoring systems track all picking activities and provide performance feedback. The system logs operator productivity, batch efficiency, and error rates for continuous improvement analysis. This data visibility enables optimization opportunities that compound productivity gains over time.

Flexible integration capabilities connect the UltraBatch to any automation technology through standard interfaces. The system communicates with WMS platforms, automation controllers, and enterprise systems to coordinate all activities seamlessly. This integration flexibility protects existing automation investments while enabling future expansion.

Your organization gains immediate productivity improvements while positioning for future growth through enhanced automation efficiency. The UltraBatch workstation transforms underperforming automation into competitive advantages that support business expansion.

Automation ROI improvement provides measurable value through increased output from existing equipment investments. Your ASRS, goods-to-person, or carousel systems handle 33% more orders without additional equipment purchases. This productivity gain often pays for the UltraBatch investment within the first year of operation.

Labor cost optimization reduces staffing requirements while improving job satisfaction through ergonomic design. Operators handle multiple orders efficiently without repetitive movements that cause fatigue and errors. This efficiency enables better workforce utilization while reducing turnover costs and training requirements.

Order cutoff time extension captures additional revenue through late-day order processing capabilities. The enhanced throughput enables you to accept orders later in the day while maintaining next-day delivery commitments. This competitive advantage drives customer loyalty and market share growth.

Peak season scalability handles volume spikes without proportional labor increases or system strain. The dynamic batching software adapts to changing order profiles while maintaining optimal efficiency. This scalability protects service levels during critical periods while controlling operational costs.

Accuracy improvements eliminate costly errors that damage customer relationships and increase administrative costs. The 99.99% accuracy rate reduces returns processing, customer service calls, and expedited shipping expenses. This quality improvement enhances customer satisfaction while reducing total cost per shipment.

Data visibility provides insights into continuous improvement and strategic planning. The system tracks performance metrics that identify optimization opportunities and capacity planning requirements. This intelligence supports data-driven decisions that maximize long-term operational efficiency.

The system operates in standard warehouse environments with minimal HVAC requirements. Network integration supports standard TCP/IP protocols with secure HTTPS communication for data protection. Compressed air requirements integrate existing pneumatic systems or standalone compressor units.

Manufacturing and distribution operations across industries rely on UltraBatch workstations to maximize automation investments while improving operational efficiency. Each industry gains specific advantages through customized batching strategies and integration capabilities.

Successful implementation requires analysis of your current automation performance, order characteristics, and operational goals. Consider these factors to ensure optimal system configuration and maximum ROI achievement.

Evaluate your existing automation utilization and throughput metrics. The UltraBatch workstation provides greatest value when automation systems operate below capacity due to picking inefficiencies rather than equipment limitations. Understanding current performance establishes baseline metrics for ROI measurement.

Analyze order profile characteristics including average lines per order, SKU velocity distribution, and seasonal variations. The dynamic batching software optimizes based on these patterns, so accurate order analysis ensures proper algorithm configuration. This analysis also identifies specific productivity improvement opportunities.

Assess operator skill levels and training requirements for transition to batch picking operations. While the UltraBatch simplifies the picking process, operators need training on new workflows and quality procedures. Plan for learning curves and productivity ramp-up periods during implementation.

Consider integration complexity with existing WMS and automation control systems. Most implementations require software customization and testing to ensure seamless operation. Plan for integration development time and potential system modifications to existing automation.

Evaluate facility layout and ergonomic requirements for workstation placement. The UltraBatch requires adequate space for conveyor integration and operator access while maintaining workflow efficiency. Consider future expansion requirements and maintenance access during planning.

Plan for performance monitoring and continuous improvement processes. The system provides extensive analytics that require analysis and action to achieve maximum benefits. Establish procedures for regular performance reviews and optimization activities to maintain productivity gains.

UltraBatch workstations offer extensive customization options to match specific operational requirements and integration needs. These options enhance functionality while accommodating future expansion and changing operational demands.

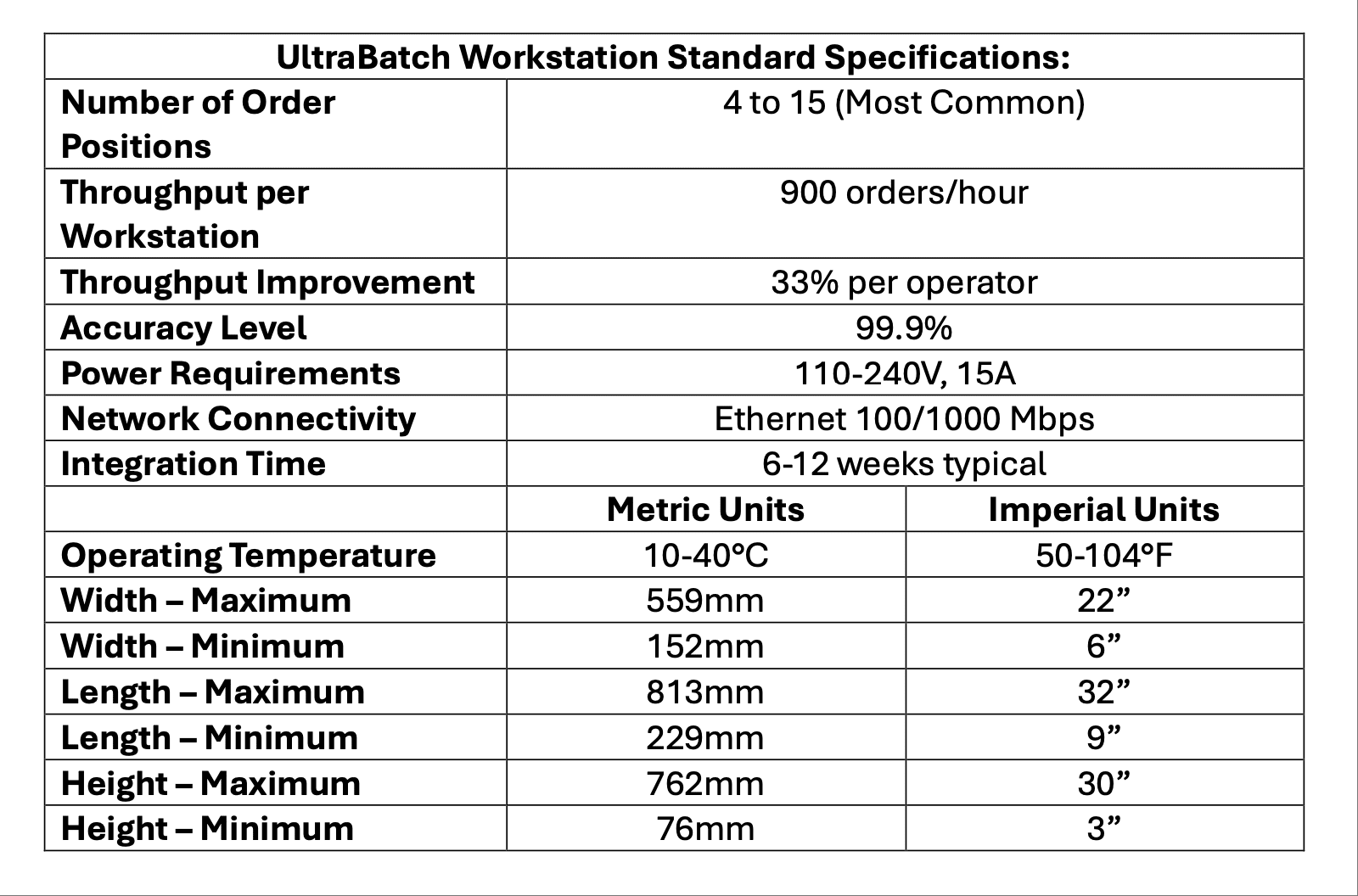

Understanding system specifications ensures proper planning for installation, operation, and integration requirements. These specifications support capacity planning and facility design activities.

The workstation operates in standard warehouse environments with minimal utility requirements. Integration with existing automation systems typically requires 4-8 weeks including software development, testing, and operator training activities.

Batch picking technology continues advancing through artificial intelligence, machine learning, and enhanced automation integration. These developments create new opportunities for productivity optimization and competitive advantage.

AI-powered batching algorithms analyze order patterns and operator performance to optimize batch composition dynamically. Machine learning capabilities adapt to changing order profiles automatically while identifying opportunities for further efficiency improvements.

Augmented reality integration provides enhanced picking guidance through smart glasses and heads-up displays. This technology eliminates the need to look away from picking tasks while providing real-time verification and quality control feedback.

Collaborative robotics integration enables human-robot collaboration for complex picking tasks. These systems handle repetitive or physically demanding activities while operators focus on decision-making and quality control responsibilities.

Predictive analytics capabilities forecast capacity requirements and identify optimization opportunities before performance issues occur. Advanced modeling predicts maintenance needs and suggests configuration changes to maximize efficiency.

IoT sensor integration provides detailed environmental monitoring and equipment performance tracking. Real-time data collection enables predictive maintenance and identifies factors that impact picking accuracy and productivity.

Advanced WMS integration creates seamless data flow between order management, inventory control, and picking operations. This connectivity enables real-time optimization and better coordination across the entire fulfillment process.

ISD – Integrated Systems Design created the UltraBatch technology and maintains unmatched expertise in dynamic batch picking implementations. Our 60+ years of warehouse automation experience ensures successful deployment and maximum ROI achievement.

Our OptimalOps-Process™ framework analyzes your specific operations before recommending solutions. This comprehensive approach identifies the optimal UltraBatch configuration while ensuring seamless integration with your existing automation systems.

Our engineering team combines deep UltraBatch expertise with practical knowledge of ASRS, goods-to-person, and pick-to-light systems from all major manufacturers. This experience enables rapid integration while avoiding compatibility issues that delay implementation.

Our proprietary UltraProducts line provides complete solution capabilities including UltraStore ASRS and UltraSert document insertion systems. This comprehensive approach creates integrated automation environments that maximize productivity across all operations.

Our project management methodology minimizes implementation risks through proven processes and comprehensive testing. We coordinate closely with your operations team to ensure smooth transitions while maintaining production schedules and service commitments.

Our ongoing support includes performance optimization services, software updates, and expansion planning assistance. This partnership approach ensures long-term success while protecting your automation investment through changing operational requirements.

Our industry expertise spans retail, 3PL, automotive, aerospace, electronics, food and beverage, and manufacturing operations. This experience enables rapid deployment while ensuring industry-specific requirements and compliance standards are met.

UltraBatch integrates with any goods-to-person, ASRS, or pick-to-light system through standard communication protocols. The workstation connects to your WMS and automation controllers via APIs, enabling seamless operation without major system modifications.

Most implementations achieve 12–18-month payback periods through labor reduction and productivity improvements. The 33% throughput increase combined with 50% labor reduction typically generates $200,000-$500,000 annual savings depending on operation size.

Yes, operators process up to 15 orders simultaneously while the system automatically manages batch flow. The ergonomic design and pick-to-light guidance enable efficient multi-order handling without confusion or errors.

Basic operator training requires 1-2 days covering system operation, pick-to-light procedures, and quality control processes. The intuitive interface minimizes learning time while comprehensive training materials support ongoing skill development.

Dynamic batching continuously optimizes order grouping based on real-time conditions and automatically manages batch flow. Static systems require manual batch setup and release, creating inefficiencies that dynamic batching eliminates.

Routine maintenance includes daily visual inspections and weekly cleaning procedures. The system provides predictive maintenance alerts while modular design enables quick component replacement without extended downtime.

Measure how efficiently your existing ASRS, goods-to-person, or pick-to-light systems operate. UltraBatch provides maximum value when automation capacity is underutilized due to picking inefficiencies rather than equipment limitations.

Establish baseline productivity metrics to calculate potential improvements. UltraBatch typically increases throughput by 33% while maintaining higher accuracy levels than manual picking processes.

Analyze volume fluctuations to determine scaling needs. UltraBatch enables handling peak volumes with existing labor while maintaining service levels that protect customer relationships.

Develop tracking systems for throughput, accuracy, and labor efficiency. Establish baseline metrics before implementation to demonstrate ROI and identify ongoing optimization opportunities.

Plan implementation around business cycles and seasonal requirements. Most UltraBatch installations require 4-8 weeks including software development, testing, and operator training activities.

Analyze order characteristics including average lines per order, SKU velocity, and seasonal variations. This analysis enables proper algorithm configuration for maximum productivity improvements.

Contact Us for More Information About UltraProducts