Home / Industry / Automotive

Automotive warehouse managers are under constant pressure to keep production lines supplied, meet just-in-time schedules, and control operational costs. You juggle large parts of inventories, complex sequencing, and tight delivery windows, all while improving accuracy, throughput, and labor.

Automotive plants require precise, on-time part deliveries.

Sequencing errors disrupt production and increase costs.

Retaining skilled workers for fast-paced environments is difficult.

Managing bulky parts and diverse SKUs strains storage capacity.

ISD’s OptimalOps-Process designs scalable automotive warehouse systems that enhance speed, precision, and flexibility. We deliver technology-agnostic solutions that optimize space, improve part sequencing, and support just-in-time operations to keep your supply chain running smoothly.

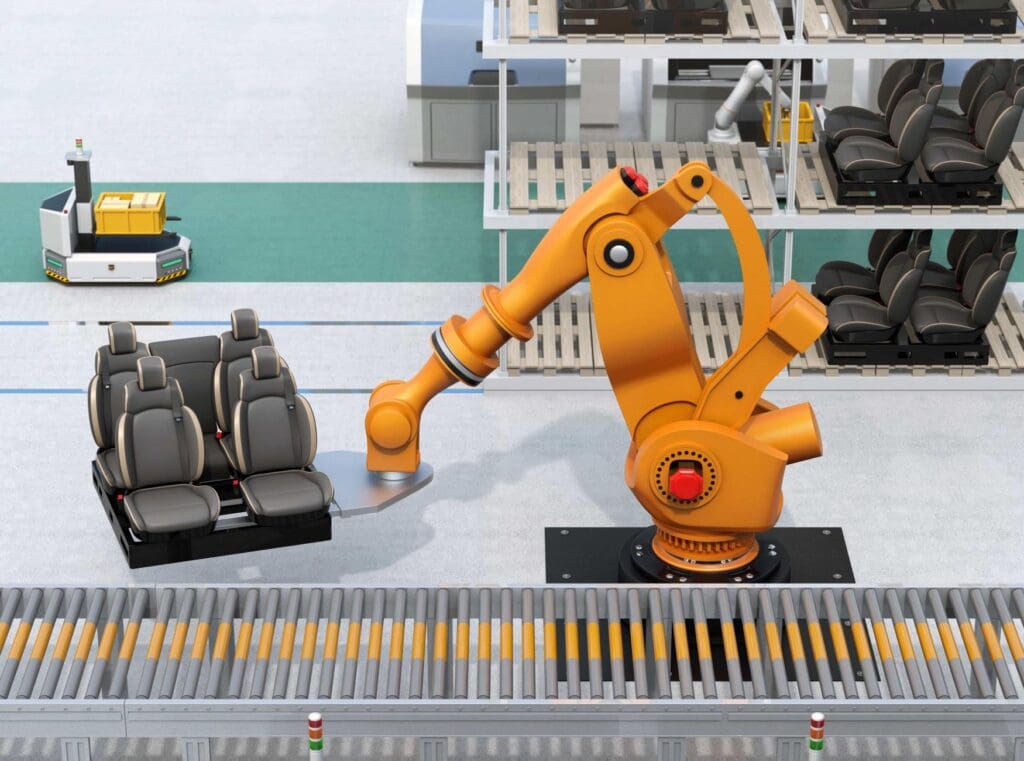

ISD automotive warehouse systems use a myriad of ASRS systems for buffering, sequencing, sortation and of course high density storage. The UltraStore Mid-Load ASRS provides the perfect blend of reliability, ease of use, and economy to solve most automotive manufacturing and assembly applications. Robotics, AMRs, and AGVs for precise part delivery, and warehouse software (WMS, WES, WCS and controls) to streamline sequencing and flow. Conveyors and pick-to-light solutions increase speed and reduce errors. Our technology-agnostic designs integrate seamlessly to boost warehouse efficiency in automotive operations.

The Vertical Lift Module (VLM), ISD’s automated storage and retrieval system, improves warehouse efficiency, is designed to improve workers productivity, accuracy, and space utilization. This VLM is a core technology for organizations seeking to optimize their storage capacities and improve operational efficiencies.

The UltraStore Mid-Load Automated Storage and Retrieval System (ASRS) represents a sophisticated warehouse automation solution designed to handle medium-weight inventory items with exceptional precision and efficiency.

The URBX robotic inventory storage and retrieval system represents a paradigm shift in the automated storage and retrieval systems ASRS world and more specifically warehouse automation. The URBX ASRS is engineered to meet the escalating market demands of increasing.

Ready to optimize your operations? As a systems integrator, ISD continuously looks for leading technologies in both material handling and information systems paired with proven operational strategies. Our solutions range from simple to highly automated, earning us the

trust and business of clients spanning decades.